Aramid 1414 grid fabric is used in soft body armor and flame-retardant protective clothing

Jul 04,2025

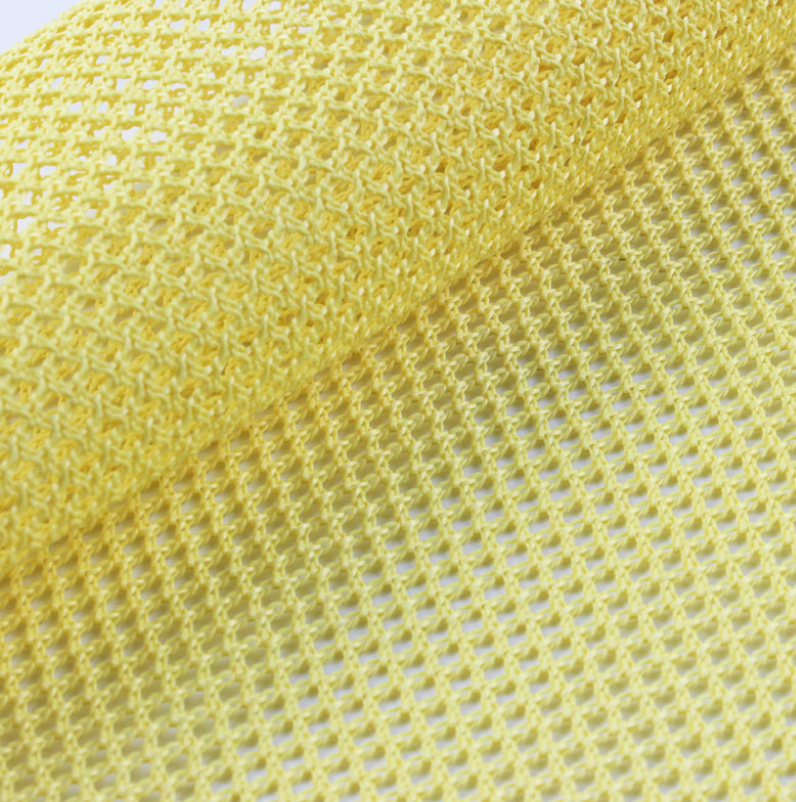

Aramid 1414 Grid Fabric

Aramid 1414 grid fabric is a mesh fabric woven from para-aramid (PPTA) fibers.

Mesh type: Square/rectangular mesh (common sizes: 6×6 mm, 10×10 mm) or plain weave.

Weight range: 100–280 g/㎡ (higher weight, stronger load-bearing capacity).

Fiber orientation:

Bi-directional weaving: Balanced warp and weft strength (used for protective clothing, blast-resistant layers);

Uni-directional weaving: 90% of fibers concentrated in one direction (used for building reinforcement fabric).

Value of mesh structure:

Mechanical enhancement advantages

Energy dissipation: Mesh nodes disperse impact force along multi-directional fibers (improved energy absorption efficiency of bulletproof vests).

Permeation composite: Mesh allows resin impregnation to form an interpenetrating structure (improved interlaminar shear strength of composite materials).

Functional adaptability

Breathability: Open mesh for heat dissipation in protective clothing;

Deformability: Mesh slides to adapt to curved surfaces.

Characteristics of Aramid 1414 Grid Fabric

① Ultra-high strength and high modulus: High tensile strength of single filaments, large modulus, and low density, achieving "lightweight and high strength".

② Low elongation at break: Small deformation under stress, high stability.

③ High temperature resistance: Long-term use temperature range -196℃~204℃, does not decompose or melt at 560℃, high strength retention rate at high temperatures.

④ Inherently flame retardant: Limiting oxygen index (LOI) of about 30%, does not melt or drip when exposed to fire, and quickly carbonizes to form a heat insulation layer.

⑤ Resistant to acid, alkali, and organic solvent corrosion, anti-UV aging, suitable for harsh environments such as chemical and marine environments.

⑥ Good insulation, suitable for electrical equipment. [The above data comes from laboratories and the internet]

Application fields of Aramid 1414 grid fabric

I. Protective and blast-resistant products

Special bulletproof equipment

Products: Bulletproof vests, helmet liners, armored vehicle protection plates.

Application method: Multiple layers of aramid grid fabric are laminated to form a composite material, and the impact energy is dispersed through the fiber grid. Plain weave fabric with a weight of 220~260 g/㎡ is used for soft bulletproof vests, reducing weight by more than 30%; it is also used in combination with ceramic plates for hard armor plates.

Advantages: High specific strength (tensile strength 4500 MPa) and low density (1.8 g/cm³), achieving lightweight protection.

Composite blast-resistant structure

Products: Aluminum foam core blast-resistant plates (used for blast walls, military shelters).

Application method:

Core structure: The upper and lower layers are aramid plain weave fabrics, with a gradient aluminum foam layer in the middle, and the layers are constrained from deformation by aramid grid fabric.

Effect: Energy absorption capacity reaches 30 J/cm³, deformation is localized under explosive impact, protecting the rear structure.

II. Building reinforcement and repair materials

Reinforcement of concrete structures

Products: Aramid unidirectional fabric (weight 280 g/㎡ or more).

Application method:

Beam bending reinforcement: Fiber direction parallel to the beam axis, pasted on the tensile side, to improve load-bearing capacity.

Column shear reinforcement: Fiber direction perpendicular to the column, wrapped around, reducing a large amount of corner grinding work.

Case: Tyvek® aramid fabric is used for bridge and tunnel reinforcement, especially suitable for curved structures such as chimneys and water towers.

Pipeline and oil and gas facility repair

Products: Circumferential aramid fiber fabric (with modified epoxy resin).

Application method: Wrapped around the defective area vertically to the pipeline axis to resist internal pressure expansion force.

Advantages: Resistant to seawater corrosion, insulation (non-conductive), suitable for submarine oil and gas pipelines.

III. Industrial protective equipment

High-temperature protective clothing

Products: Firefighting suits, welding suits, racing suits (weight 220–260 g/㎡).

Characteristics:

Flame retardancy: Limiting oxygen index LOI > 28, carbonization without melting when exposed to fire.

Cut resistance: High density of plain weave, cut resistant.

Application: The outer layer uses aramid grid fabric, and the inner lining is flame-retardant adhesive, combining flexibility and protection.

Cut-resistant gloves and protective gear

Products: Industrial gloves, sports arm guards (weight 220 g/㎡).

Advantages: 40% lighter than metal wire gloves, wear-resistant and resistant to chemical corrosion.

IV. Composite material reinforced components

Aerospace and transportation components

Products: Aircraft interior panels, UAV shells, high-speed rail car body panels.

Application method:

Aramid paper honeycomb core material: Lightweight honeycomb structure (density 0.03 g/cm³), used for weight-reducing load-bearing components.

Resin matrix composite material: Grid cloth is pre-impregnated with resin and then molded, reducing weight by 30% compared to aluminum.

High-performance tires and hoses

Products: Racing tires, high-pressure hoses.

Function: Replaces steel cord, reduces rolling resistance, and improves tear resistance.

PREVIOUS:

Related Posts

Contact Us

E-mail:

gdkaidun@163.com

Phone/WeChat:

86-131-3828-6677

Address:

Room 401, Building 21, No. 1, Keqing Road, Yundonghai Street, Sanshui District, Foshan City, Guangdong Province