Environmental characteristics of basalt fiber: A revolutionary breakthrough in green materials

Jul 02,2025

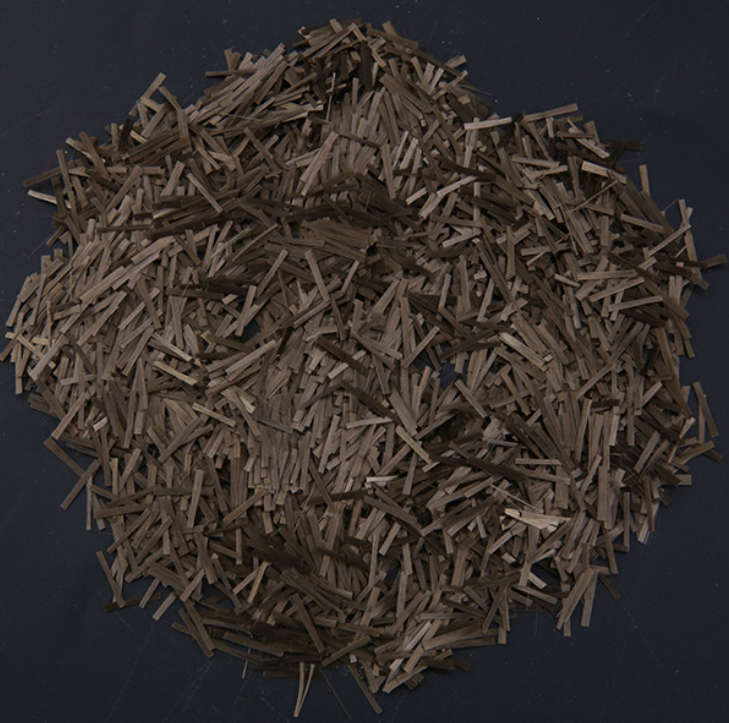

Basalt fiber is an inorganic fiber material made from natural basalt as raw material, which is melted at a high temperature of 1450-1500℃ and then drawn into high-speed fibers through a platinum-rhodium alloy die. Its main components include silicon dioxide (SiO₂, 45-60%), alumina (Al₂O₃, 12-18%), iron oxide (FeO+Fe₂O₃, 5-15%), etc., which are highly consistent with the composition of the earth's crust, making it a truly "nature-derived" material.

Compared with traditional materials, the production process of basalt fiber demonstrates significant environmental advantages:

Zero raw material processing: Basalt ore does not require chemical purification; after crushing, it can be directly melted, avoiding pollution from acid washing and alkali treatment.

Low-energy consumption process: Production energy consumption is only 30% of that of glass fiber, and carbon emissions are 80% lower than those of carbon fiber.

Zero waste: Production waste can be 100% recycled and re-melted, with no solid waste discharge.

Non-toxic: It does not contain harmful elements such as boron and fluorine, and does not release VOCs (volatile organic compounds) during production.

Biocompatibility: The fiber surface is compatible with microbial communities and can be used in ecological restoration projects.

Water resource protection: Water consumption is 40% less than that of glass fiber, and it can be recycled.

Characteristics of Basalt Fiber

Mechanical Properties

Tensile strength: 3000-4800 MPa (superior to ordinary steel)

Elastic modulus: 89-110 GPa

Density: 2.6-2.8 g/cm³ (3 times lighter than steel)

Environmental Tolerance

Temperature resistance: Stable operation from -260℃ to 800℃, no toxic gases are released during fire.

Corrosion resistance: In acidic and alkaline environments with pH 2-12, the annual strength loss rate is <3%.

Radiation resistance.

Application Fields of Basalt Fiber

Construction Engineering: The backbone of low-carbon cities

Concrete reinforcement: Replacing steel bars, solving rust problems, and extending the service life of buildings.

Seismic structure: Fiber mesh reinforcement of historical buildings, with a cost reduction of 40% compared to carbon fiber solutions.

Green building materials: Composite with bamboo to produce fireproof and heat-insulating boards, with a thermal conductivity as low as 0.032 W/(m·K).

Transportation Field: A revolution in lightweighting

New energy vehicles: Battery pack protective shells are 30% lighter, increasing the range by 5-8%.

Rail transit: Fiber-reinforced brake pads, extending the service life by 2 times and reducing brake dust pollution.

Shipbuilding: Marine corrosion-resistant composite materials for ship hulls, reducing maintenance frequency.

Environmental Engineering: A powerful tool for ecological restoration

Pollution control: Heavy metal adsorption filter membranes, with an adsorption rate of 99.7% for lead and cadmium.

Soil reinforcement: Fiber geotextiles prevent desertification and promote vegetation restoration.

Marine protection: Artificial reef substrates, supporting the attachment and growth of coral larvae.

Energy Field: A booster for clean technology

Wind turbine blades: 15% lighter than glass fiber blades, improving power generation efficiency.

Hydrogen energy storage and transportation: Reinforcement layer for Type IV hydrogen storage tanks, with a burst pressure exceeding 87.5 MPa.

Photovoltaic brackets: Weather resistance is 5 times higher than that of aluminum alloy, suitable for salt-alkali land power stations.

PREVIOUS:

Related Posts

Contact Us

E-mail:

gdkaidun@163.com

Phone/WeChat:

86-131-3828-6677

Address:

Room 401, Building 21, No. 1, Keqing Road, Yundonghai Street, Sanshui District, Foshan City, Guangdong Province