Pre-oxidized silk aerogel felt coated battery cells solve the thermal insulation problem of lithium battery packs

May 28,2025

Core characteristics of pre-oxidized fiber aerogel felt

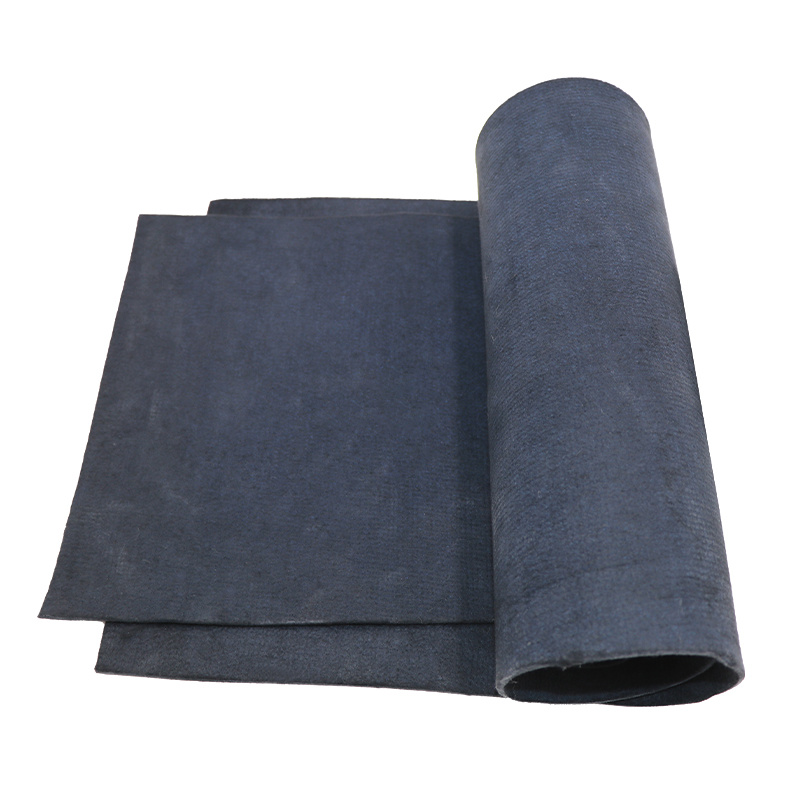

Pre-oxidized fiber aerogel felt is an ultralight, nanoporous material composed of a polyacrylonitrile pre-oxidized fiber (pre-oxidized fiber) framework and silica aerogel composite.

Excellent thermal insulation performance

Low thermal conductivity: Thermal conductivity of 0.018-0.023W/(m·K) at room temperature, only 1/3 of traditional ceramic fiber felt, and ≤0.035W/(m·K) even at 800℃.

Wide temperature range: Continuous use temperature -200℃ to 650℃, instantaneous temperature resistance up to 1000℃ (the aerogel maintains structural stability after carbonization).

Lightweight and flexibility

Extremely low density: 150-300kg/m³, lighter and stronger than rock wool (100-200kg/m³), with high tensile strength.

Bendable construction: Bending radius ≤5 times the thickness, suitable for pipe and irregularly shaped equipment wrapping, reducing seam heat loss.

Flame retardancy and chemical stability

Fire rating A1, LOI≥35%, no toxic gases released when exposed to fire.

Acid and alkali resistant (pH 2-12), hydrolysis resistant, and resistant to industrial flue gas corrosion (such as sulfuric acid dew point corrosion).

Acoustic and compressive properties

Low noise reduction coefficient, sound absorption effect in the 125-4000Hz frequency band is better than glass wool.

Rebound rate ≥90% under 10% compression deformation, thickness loss <5% after 1000 cycles of compression.

Application fields of pre-oxidized fiber aerogel felt

New energy and energy storage equipment

Lithium battery pack thermal insulation: 3mm thick aerogel felt wraps the battery cells, suppressing the spread of thermal runaway, temperature difference control <5℃ (thermal runaway test).

Liquid hydrogen tank insulation: Resistant to -253℃ cryogenic environment, reducing evaporation loss.

Industrial high-temperature equipment

Petrochemical pipeline insulation: Replacing alumina silicate fiber, reducing weight by 50% and improving construction efficiency by 3 times (no need for multi-layer wrapping).

Steel plant hot air duct: Surface temperature ≤60℃ under 650℃ operating conditions, improving energy efficiency.

Aerospace field

Spacecraft thermal protection system (TPS): 10mm thick felt is used in the re-entry capsule insulation layer, resistant to 1600℃ aerodynamic heating (short-term).

Ship engine room: Combines fire prevention and noise reduction functions, passing MIL-STD-1623A impact resistance test.

Building and transportation fields

Ultra-low energy consumption buildings: 20mm thick felt is used for exterior wall insulation, U-value ≤0.15W/(m²·K), meeting passive house standards.

New energy vehicle battery compartment: 5mm thick felt fire isolation, 70% weight reduction compared to traditional solutions, 3-5% increase in range.

PREVIOUS:

Related Posts

Contact Us

E-mail:

gdkaidun@163.com

Phone/WeChat:

86-131-3828-6677

Address:

Room 401, Building 21, No. 1, Keqing Road, Yundonghai Street, Sanshui District, Foshan City, Guangdong Province