Elevator shaft fire barrier: Aramid flame-retardant fabric interlayer effectively blocks the spread of fire

May 12,2025

Elevator Shafts: A Deadly Hidden Danger of the "Chimney Effect" in High-Rise Buildings

According to fire statistics, more than 60% of casualties in high-rise fires are caused by the spread of fire through elevator shafts. When a fire occurs, the shaft acts like a giant chimney, with the fire spreading at a speed of up to 10 m/s and temperatures exceeding 1000℃ in an instant. Traditional fire-resistant materials frequently fail under extreme conditions, while Aramid Non-Woven Fabric Fire-Resistant Layer is reshaping the safety defenses of high-rise buildings with its defense-grade protective performance.

Chimney Effect Accelerates Fire Spread

Vertical spread speed: 5-10 times faster than horizontal spread

Temperature surge: Reaches 800-1000℃ within 30 seconds

Toxic gas diffusion: Carbon monoxide concentration exceeds 1000 ppm

Traditional Fire-Resistant Materials

Fire-resistant boards, as traditional fire-resistant materials, are prone to high-temperature deformation and detachment, and their weight is excessive (>20 kg/m²), easily causing collapse in case of fire.

Rock wool layers fail when wet, and fiber shedding is carcinogenic.

Calcium silicate boards crack and disintegrate, and have poor earthquake resistance.

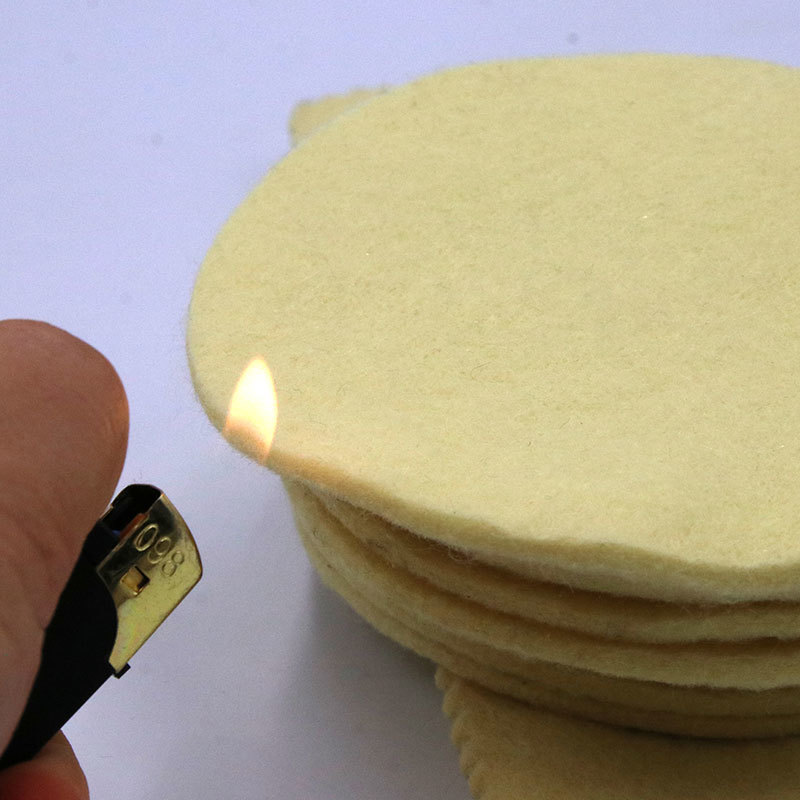

Aramid Flame-Retardant Fireproof Fabric

✅ Inherent flame retardancy: LOI≥32% (self-extinguishing 0.5 seconds after removing flame)

✅ High-temperature resistance: Long-term resistance to 300℃, short-term resistance to 1000℃ impact

✅ Lightweight and high-strength: Surface density only 300g/m² (load-bearing >500N/cm)

✅ Earthquake and tear resistance: Elongation at break <3% (no deformation under strong earthquakes)

✅ Environmentally friendly and durable: Environmentally friendly materials, do not produce toxic gases when burned, and are biodegradable

Aramid non-woven fabrics support customized production:

Flexible adjustment of weight (100-800gsm), thickness (1-6mm), width (1-2.4m), and composite processes (composite adhesive, composite aluminum foil, blended pre-oxidized yarn, blended polyimide, etc., such as anti-static, waterproof) to meet different protection needs.

Multi-Scenario Protection Solutions

1. New Building Pre-installation System

Modular installation: Fire-resistant partitions are installed every 3 floors, improving construction efficiency by 70%

Intelligent temperature-sensitive linkage: Automatically expands and seals gaps when encountering fire

Smoke guiding design: Directional smoke exhaust channels reduce toxic gas accumulation

2. Existing Building Retrofit

Non-destructive installation: Uses adhesive + mechanical fixation double insurance

Ultra-thin design: Thickness only 5mm, does not affect elevator operation

Fast construction: Single-layer renovation takes <2 hours

3. Special Venue Customization

Explosion-proof type: Shock wave pressure resistance 0.3MPa (for chemical enterprises)

Corrosion-resistant type: Passes 96-hour salt spray test (suitable for coastal buildings)

Transparent and visible type: Maintains 80% light transmittance (optimal for hospitals/shopping malls)

PREVIOUS:

Related Posts

Contact Us

E-mail:

gdkaidun@163.com

Phone/WeChat:

86-131-3828-6677

Address:

Room 401, Building 21, No. 1, Keqing Road, Yundonghai Street, Sanshui District, Foshan City, Guangdong Province