Aramid 1313 fiber, flame-retardant and high-temperature resistant, used for industrial kiln seals

May 21,2025

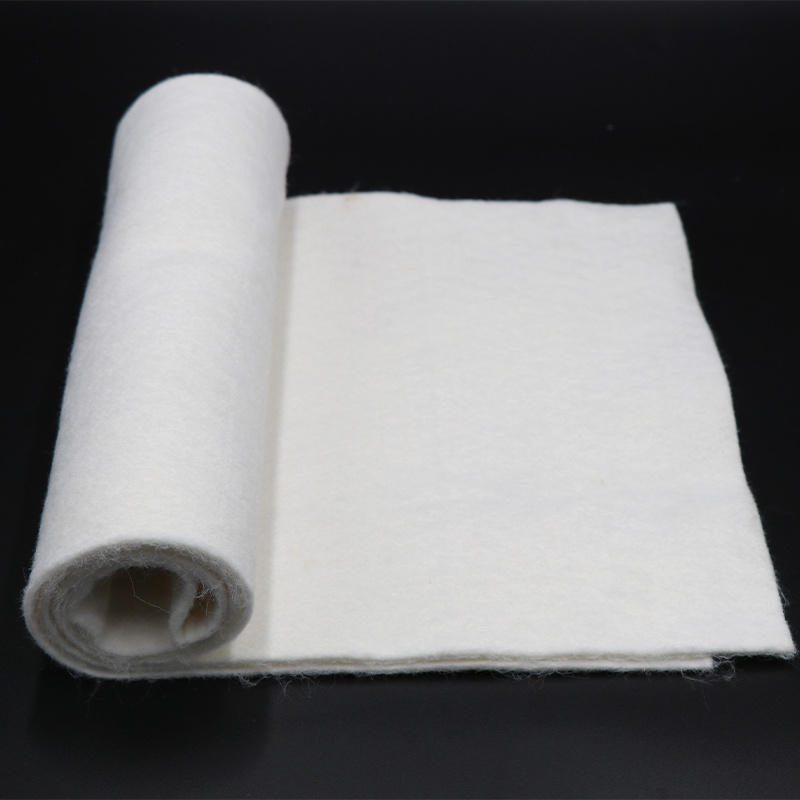

Core Characteristics of Aramid 1313 Fiber

Flexible Filling and Sealing Performance

Weight (300g/㎡): Between loose fibers and dense thick felt, it combines flexibility and moderate compressive strength, suitable for filling irregular gaps or as a sealing material.

Thickness (3mm): Thin design enhances adhesion, compression rebound rate ≥80%, it can still recover to its original state after repeated pressure, adapting to dynamic sealing needs.

High Temperature Resistance and Flame Retardancy

Long-term temperature resistance of 200℃, short-term tolerance of 250℃ high temperature, limiting oxygen index (LOI) >28%, carbonization without melting when encountering fire, blocking flame spread.

3mm thickness can be used in multiple layers to enhance the heat insulation and sealing effect in high-temperature environments (such as furnace door gap filling).

Chemical and Mechanical Stability

Resistant to weak acids, weak alkalis and oil stains, excellent hydrolysis resistance, suitable for corrosive environments such as chemical plants and ships. Wear-resistant and anti-aging, the surface fibers are not easy to fall off after repeated friction, and the service life is long.

Multiple Width Adaptability

5cm width: Adaptable to narrow gap sealing (such as pipe flanges, valve interfaces), reducing material waste.

6-7cm width: Used for wider gaps (such as fire door edges, industrial kiln seams), single-strip coverage is more efficient.

Application Scenarios of Aramid 1313 Fiber

High-Temperature Industrial Sealing and Heat Insulation

Industrial kiln sealing strip: 6cm wide strip fills the furnace door gap, withstands 300℃ high temperature, reduces heat loss and prevents the infiltration of external cold air.

Pipe flange wrapping: 5cm wide strip wraps the flange seam, corrosion-resistant and highly sealed, replacing traditional asbestos gaskets.

Fire Protection and Safety Protection

Fire door filling layer: 7cm wide strip embedded in the edge of the door frame, expands and carbonizes when encountering fire, delaying smoke penetration, and meeting the 1-2 hour fire resistance limit.

Cable fire prevention blocking: 5cm wide strip fills the cable bridge through-wall holes, flame-retardant and aging-resistant.

Transportation and Construction

High-speed rail/ship cabin sealing: 6cm wide strip is used for cabin doors and porthole seams, shock absorption, sound insulation and resistance to salt spray corrosion.

Building curtain wall fire prevention blocking: 5-7cm wide strip fills the expansion joints between the glass curtain wall and the structure, combining fire prevention and elastic deformation requirements.

Special Equipment and New Energy

Lithium battery pack fire isolation: 5cm wide strip separates the battery cells, inhibits the spread of thermal runaway, and withstands electrolyte corrosion.

Solar panel frame sealing: 6cm wide strip fills the gap between the photovoltaic panel and the bracket, resistant to ultraviolet rays and humid and hot environments.

Aramid 1313 fiber (300g/㎡, 3mm thick, 5-7cm wide) is an ideal choice for industrial sealing, fire prevention and blocking applications due to its flexible sealing, high temperature resistance and multi-specification adaptability.

Different widths precisely match the gap size, replacing traditional rubber and ceramic fiber materials in high-temperature, corrosive or dynamic load environments, and promoting the upgrading of sealing solutions towards lightweight and long-life.

Related Posts

Contact Us

E-mail:

gdkaidun@163.com

Phone/WeChat:

86-131-3828-6677

Address:

Room 401, Building 21, No. 1, Keqing Road, Yundonghai Street, Sanshui District, Foshan City, Guangdong Province