High-strength polyimide fire blanket, covering electric welding spark protection operation safety

May 05,2025

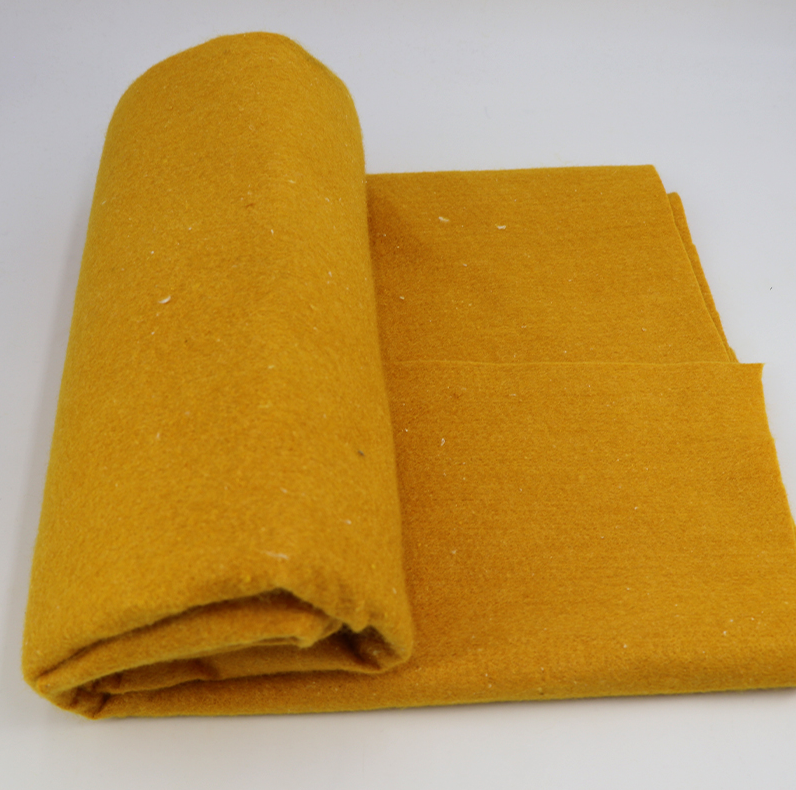

High-strength fire blanket made of polyimide

At industrial manufacturing and construction sites, welding operations are constantly threatened by flying sparks and molten slag. Statistics show that over 35% of industrial fires are caused by welding sparks. Traditional asbestos fire blankets, while offering some protection, have drawbacks such as being heavy, easily damaged, and posing a carcinogenic risk. Today, high-strength fire blankets made of polyimide materials are redefining safety standards for welding operations.

Polyimide fire blanket

1. Excellent fire resistance

Maximum temperature resistance: 500℃ (long-term) / 1000℃ (short-term)

Oxygen index > 36, meeting the standard for flame-retardant materials

Does not melt or drip when exposed to fire, effectively preventing secondary ignition

2. Outstanding mechanical strength

Tensile strength > 100 MPa

Tear strength > 50 N/mm

Excellent wear resistance, service life of more than 5 years

3. Excellent chemical stability

Acid and alkali resistant, corrosion resistant

Oil-resistant, prevents solvent penetration

Does not mildew or age

4. Environmental safety and multi-functionality

Free of asbestos and other harmful substances

No toxic smoke is released during combustion

Recyclable

Combines fire prevention, heat insulation, and anti-static functions

Can be combined with other materials to enhance performance

Applications of Polyimide Fire Blanket

Welding operation protection

Used as a welding fire blanket

Covers flammable materials, isolating flying sparks

Typical specifications: 1.5 mm thick, temperature resistance 800℃

Chemical pipeline protection

Wraps easily corroded pipelines

Double protection against fire and corrosion

Typical application: Chemical plant reactor pipeline systems

Tank fire isolation

Covers oil tanks, gas tanks, and other hazardous areas

Prevents external fire sources from igniting

Case study: Tank farm renovation project at a certain oil refinery

Building fire separation

Temporary fire curtain

Fire isolation in construction areas

Protection of escape routes in high-rise buildings

Transportation field

Fire shield for new energy vehicle battery packs

Fire-resistant layer for high-speed rail and aircraft interiors

Fire isolation in ship engine rooms

Power system protection

Fire shield for substation equipment

Fire isolation for cable trenches

Fire-resistant lining for electrical cabinets

Related Posts

Contact Us

E-mail:

gdkaidun@163.com

Phone/WeChat:

86-131-3828-6677

Address:

Room 401, Building 21, No. 1, Keqing Road, Yundonghai Street, Sanshui District, Foshan City, Guangdong Province