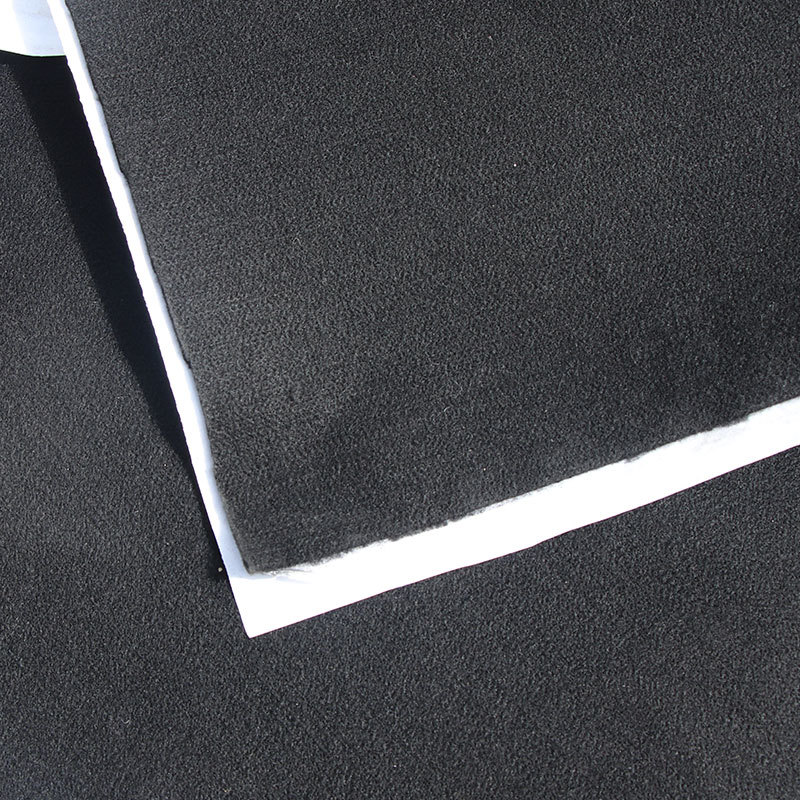

Pre-oxidized silk-backed non-woven fabric is used for the outer walls of electric fireplaces and boilers.

Sep 28,2025

Pre-oxidized silk-backed nonwoven fabric is a composite material created by processing pre-oxidized fibers (pre-oxidized silk) into a felt-like structure through a nonwoven manufacturing process, and then laminating double-sided adhesive onto one side. It combines the exceptional high-temperature resistance and flame-retardant properties of the pre-oxidized silk itself with the convenient installation features provided by the back adhesive.

1. Excellent high-temperature resistance and flame retardancy

High-temperature resistance: Pre-oxidized fibers, an intermediate product in carbon fiber production, are made from polyacrylonitrile (PAN) precursor filaments through a low-temperature oxidation process. This unique structure enables them to maintain stable performance over extended periods in temperature ranges from -70°C to 350°C—and even withstand brief exposure to flame temperatures exceeding 1000°C without melting.

Flame Retardant: It boasts an exceptionally high Limiting Oxygen Index (LOI)—typically exceeding 40% (while oxygen concentration in air is about 21%)—which means it’s highly resistant to ignition in ordinary atmospheric conditions. Even if exposed to an open flame, it can quickly self-extinguish once removed from the heat source, without melting or dripping, and effectively prevents fire from spreading.

2. Excellent chemical stability

Preoxidized carbon fibers exhibit excellent resistance to most acids, bases, salts, oils, and organic solvents, making them highly resistant to corrosion or aging. This enables them to maintain stable performance over the long term in harsh environments such as chemical processing and metallurgy.

3. Excellent thermal and sound insulation performance

Thermal insulation: Its fibrous structure traps abundant still air, making it an excellent thermal insulator with a low thermal conductivity that effectively blocks heat transfer.

Sound insulation: The fluffy, porous fiber structure effectively absorbs sound wave energy, delivering excellent sound absorption and insulation performance.

4. Convenient applicability during construction (thanks to the adhesive layer)

The adhesive layer (high-temperature resistant adhesive) is covered with release paper for protection. When using, simply peel off the release paper, and you can directly apply the material onto the surface of the object to be treated—such as metal, plastic, glass, and more. Installation is incredibly easy and quick, requiring no additional fasteners or complicated processes, thereby significantly boosting construction efficiency.

5. Excellent Physical Properties

It boasts excellent flexibility, tensile strength, and tear resistance, making it easy to cut, bend, and wrap around components of various complex shapes.

Thanks to its core features of high-temperature resistance, flame retardancy, and thermal insulation, coupled with the convenient installation provided by its adhesive backing, pre-oxidized silk-backed nonwoven fabric plays a vital role in numerous industries that demand stringent safety and thermal management standards.

Select the appropriate product specifications based on the operating temperature of the actual application environment, whether direct open-flame contact is required, the type of chemical medium involved, and the desired thickness/gauge.

1. Industrial High-Temperature Protection and Sealing

High-temperature equipment thermal insulation : Used for pasting onto the surfaces of various high-temperature pipelines, boiler outer walls, heat exchangers, industrial kilns, engine exhaust pipes, drying equipment, and more. It effectively reduces heat loss, conserving energy, while also preventing personnel from suffering burns when coming into contact with equipment surfaces—thus providing essential safety protection.

High-temperature sealing gasket : Used at high-temperature flange connections, kiln doors, oven doors, boiler doors, and other joint areas. It can fill in minor irregularities on metal surfaces, creating an effective seal that prevents heat and medium leakage. Additionally, thanks to its non-combustible properties, it offers significantly higher safety compared to conventional rubber or plastic gaskets.

Welding and Cutting Operation Safety Measures : In scenarios such as shipbuilding, steel structure construction, and pipeline welding, it serves as a temporary fire blanket or fire-resistant curtain. It can be directly applied or draped over nearby combustible materials to prevent flying sparks and molten slag from igniting fires.

2. Fire Protection and Public Safety

Fire blanket and escape blanket : It is one of the preferred materials for manufacturing household and commercial fire blankets. When a cooking oil pan catches fire or a small solid object ignites, covering the source quickly cuts off the oxygen supply, effectively extinguishing the blaze. At a fire scene, after being soaked with water, it can be draped over the body as an escape blanket, shielding against intense heat and flames while buying precious time for evacuation.

Fire Isolation and Barriers During building construction and renovation—especially during hot-work operations—it serves as a temporary fireproof curtain or barrier, separating the work area from zones storing flammable materials, effectively preventing sparks from spreading and fires from escalating. It is also used for fire-stopping applications in cable shafts and around pipe penetrations.

3. Transportation Sector

Rail transit (high-speed rail, bullet trains, subways) : Used on the back sides of interior panels in train compartments (such as wall and ceiling panels), as well as the backs and bottoms of seats, serving as a fire-resistant and heat-insulating layer. In the event of a fire inside the compartment, it can effectively prevent flames from spreading into the interior materials and toward the vehicle’s structural framework, slowing down the fire and buying valuable time for passenger evacuation and rescue operations.

The engine compartment in the automotive industry : Applied to the inner side of the engine hood, firewall, and exhaust pipe heat shields, it delivers highly effective soundproofing and thermal insulation, protecting other plastic components within the engine compartment from high-temperature baking and aging—while also enhancing driving and passenger comfort.

New Energy Vehicles : Used for thermal management and fire isolation around and beneath the battery pack, providing an additional safety barrier.

Aerospace and Marine : Used as a fire-resistant and thermal insulation layer for aircraft cabin interiors and equipment compartments, as well as for sealing and insulating ship bulkheads and doors, meeting stringent safety standards.

4. Architecture and Building Materials Field

Architectural soundproofing and thermal insulation materials : As a wall-filling material or applied to interior walls, it simultaneously enhances the building's thermal insulation performance and fire resistance rating.

Fire Doors and Fire-Resistant Rolling Shutters : Used to fill the core board of fire doors or install in the interlayer of fire-resistant rolling shutters, it effectively blocks heat transfer when exposed to fire, delaying the spread of flames.

5. Electronics, Electrical Engineering, and Household Applications

Household appliances : Used inside heating appliances such as ovens, microwave ovens, heaters, air fryers, and electric fireplaces, it is attached to the outer walls of the cavities as a thermal insulation layer, preventing the exterior from overheating while enhancing thermal efficiency.

Electronic devices : Used inside LED lighting fixtures (especially high-power spotlights), power adapters, amplifiers, and more—applied between heat-generating components (such as chips or MOS transistors) and the housing or other plastic parts—to prevent heat buildup that could lead to equipment failure or deformation of the casing. It serves both as thermal insulation and a critical safety safeguard.

6. Other Industrial and Consumer Sectors

Chemical Industry Corrosion Protection and Thermal Insulation : Used as an outer-layer protection for tanks and pipelines in corrosive environments, thanks to its excellent chemical resistance.

Personal Protective Equipment (PPE) : As a thermal insulation layer, it is used for localized reinforcement in protective garments designed for high-temperature work environments, such as fire-fighting suits, welding suits, and steelmaking attire.

Everyday and DIY Uses : Such as for use as incense burner mats, electric iron insulation pads, model-making applications, and other scenarios requiring heat resistance and flame retardancy.

PREVIOUS:

Related Posts

Contact Us

E-mail:

gdkaidun@163.com

Phone/WeChat:

86-131-3828-6677

Address:

Room 401, Building 21, No. 1, Keqing Road, Yundonghai Street, Sanshui District, Foshan City, Guangdong Province