Share to

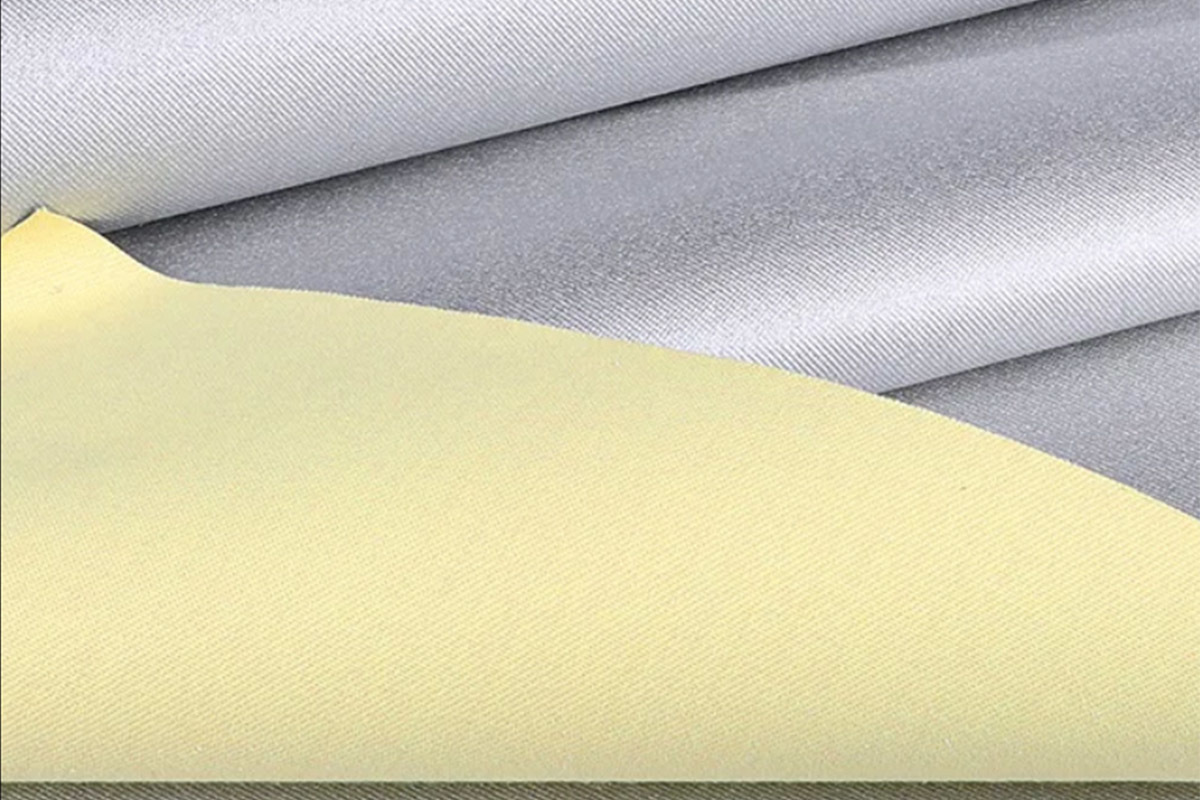

Polyimide Woven Fabric

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Features

- Specifications

- Applications

-

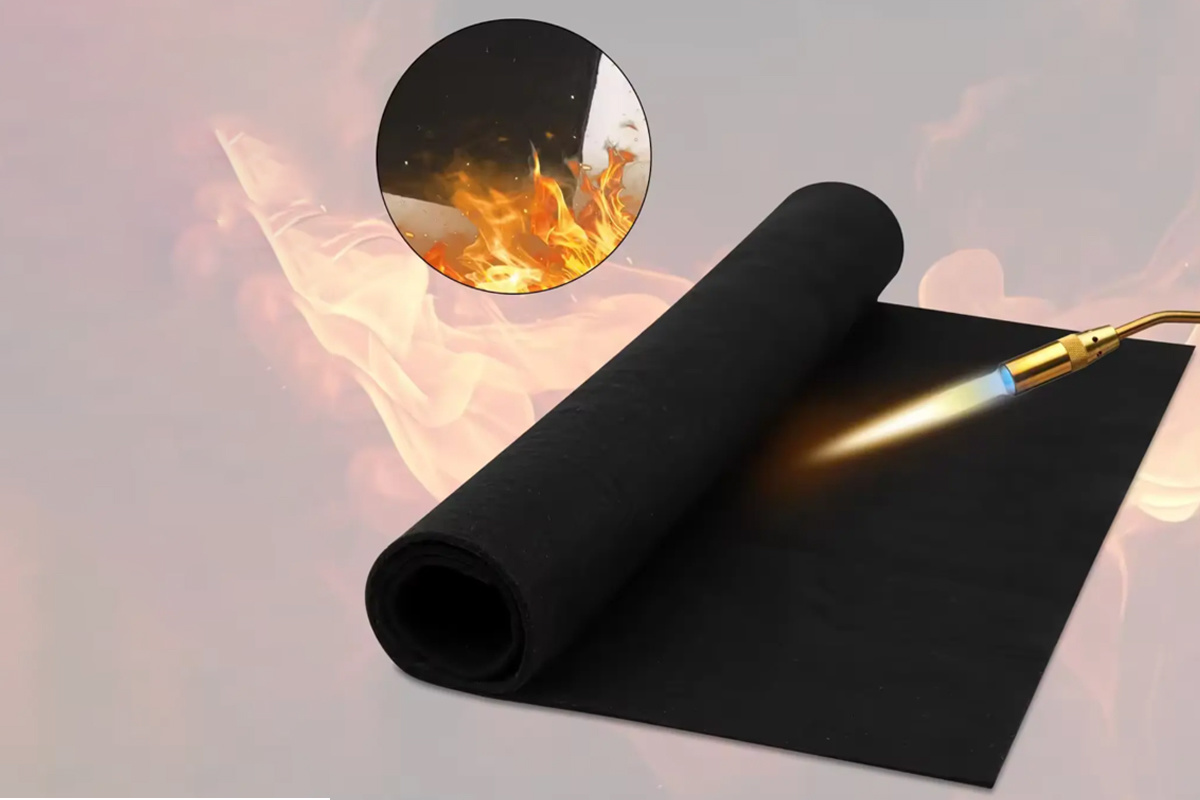

1. High-temperature resistance : Long-term use can withstand temperatures up to 250°C or higher, while short-term exposure can endure extremely high temperatures exceeding 500°C without melting.

2. Low-Temperature Resistance : It maintains excellent flexibility and remains non-brittle even at a liquid helium temperature of -269°C.

3. High Limiting Oxygen Index : Typically above 38%, it is a Inherently flame-retardant The material self-extinguishes immediately after being removed from an open flame and does not burn or drip.

4. Excellent Thermal Stability : Under high temperatures, it not only maintains its shape but also exhibits minimal degradation in physical and mechanical properties, with outstanding dimensional stability.

5. Excellent chemical stability It exhibits excellent resistance to most organic solvents, acids, bases, and more, as well as being resistant to hydrolysis and radiation.

6. Excellent Mechanical Properties : High strength, high modulus, excellent wear resistance—making the resulting fabric robust and long-lasting.

7. Excellent Electrical Insulation : It maintains stable insulation performance under both high and low-temperature conditions, exhibiting extremely high reliability.

8. Safety and Environmental Protection : It does not generate harmful substances during the production and processing stages, emits extremely low smoke when burned, and releases minimal amounts of toxic gases.

-

Available in a variety of sizes and specifications, custom options accepted.

Guangdong Kaidun New Materials Co., Ltd. is a leading factory specializing in fire-resistant cotton, equipped with its own factory workshops and professional production lines that manufacture a wide range of high-performance fiber products. These high-performance fiber products can all be customized according to customer requirements.

-

1. High-Temperature Industry

High-Temperature Flue Gas Dust Removal : Baghouse dust removal systems (filter bags), used for flue gases from boilers in industries such as power, steel, and cement, represent one of their largest application areas. They can effectively handle high-temperature and highly corrosive flue gases.

Thermal insulation material : As thermal insulation sleeves, insulation blankets, expansion joints, and more for high-temperature pipelines and equipment.

Welding Protection : Welder's protective blanket and fireproof barrier fabric, designed to prevent sparks from flying and igniting flammable materials.2. Aerospace

Spacecraft Thermal Protection : Used as thermal insulation and flame-retardant layers for rockets and spacecraft, protecting them from the extreme heat during re-entry into the atmosphere.

Aircraft interior materials : Seat covers, cabin wall panels, and more—significantly enhancing aviation safety standards (compliant with FAR 25.853 airworthiness requirements).

Flexible Insulation Felt : Used for thermal insulation around aero-engines.3. Specialized Protection

Firefighting suit : Providing firefighters with ultimate thermal protection and flame-retardant safety.

Military uniform Flame-retardant combat uniforms for special forces units such as tank crews, pilots, and naval personnel.

Industrial Protective Clothing : High-temperature workwear designed for workers in industries such as metallurgy, petrochemicals, and power grids.

4. High Technology

Composite material reinforcement As a reinforcing material for high-performance resins such as PI and epoxy resin, it is used to create high-temperature-resistant, high-strength composite materials (PI/PI composites), which find applications in aircraft components, missile casings, and more.

Electrical Insulation Materials : Used for insulation kits, slot insulation, and more in Class H and Class C motors and transformers.

Honeycomb Core Material : Alternative or upgraded materials for aerospace-grade Nomex honeycomb.

Enterprise Advantages

Guangdong Kaidun New Materials Co., Ltd.

The layout of the entire workshop is reasonable, and the equipment is placed in an orderly manner, which not only ensures the smoothness of the production process but also improves work efficiency. Advanced production equipment and technologies are adopted in the workshop to ensure the stability of product quality and the efficiency of production efficiency.

In terms of the environment, the factory workshop effect picture shows a clean and bright production environment. The workshop is equipped with a good ventilation system and lighting equipment, providing comfortable working conditions for workers. At the same time, the workshop also pays attention to environmental protection and energy conservation, adopting environmentally friendly materials and energy-saving equipment to reduce energy consumption and pollution during the production process.

In terms of safety management, the factory workshop effect picture also reflects a high degree of attention. The workshop is equipped with complete safety facilities and warning signs to ensure the safety and health of workers during the production process. In addition, the workshop is also equipped with professional safety management personnel who are responsible for supervising and managing safety matters during the production process to ensure the safety and stability of production.

Production drawing of aramid filament woven fabric

Packaging and delivery of pre-oxidized fibers

Qualification Certification

Various qualification certifications obtained by Kaitun Industrial, demonstrating its professional capabilities in meeting standards in the field of high-performance fiber material textiles, highlighting that its products comply with strict quality, safety and industry regulatory requirements, providing strong support for the enterprise's stable development and market expansion.

Keyword:

Polyimide Woven Fabric

Inquire Now

We will contact you within one working day. Please pay attention to your email.

Related Products

Aramid silver-coated composite fabric