Share to

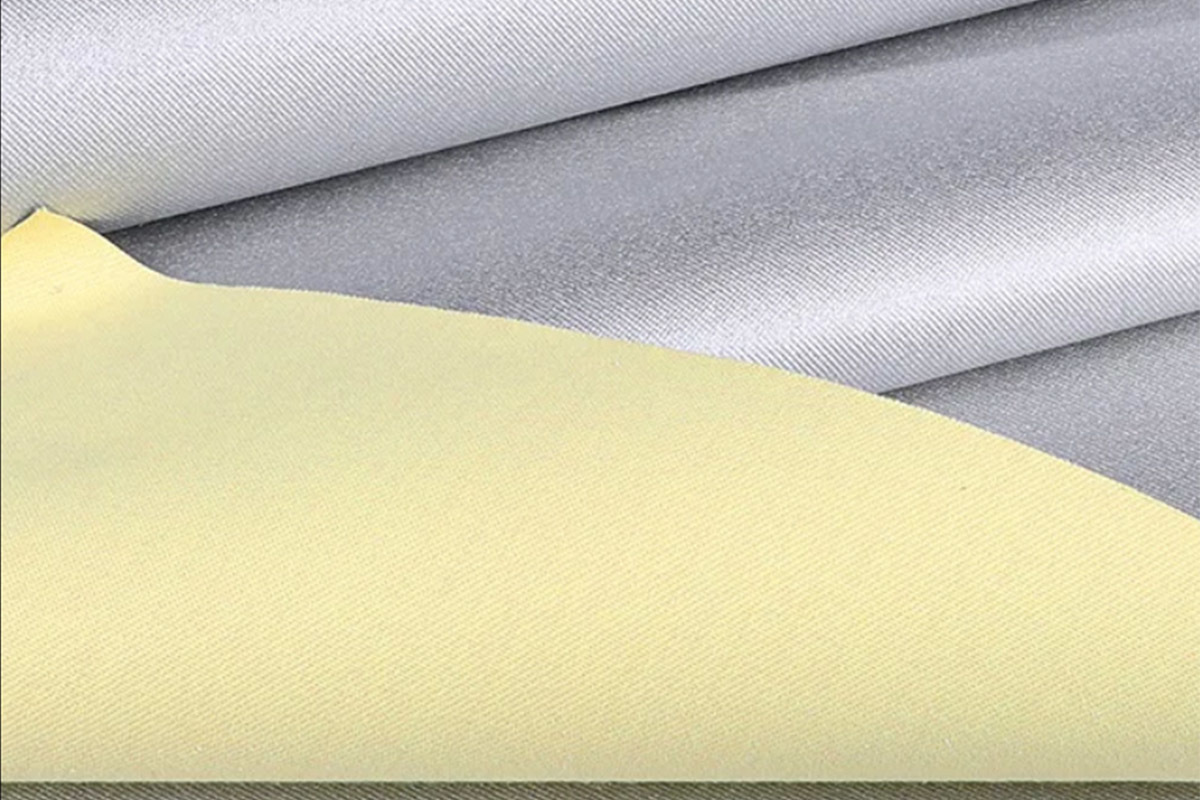

Aramid crimped fiber

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Features

- Specifications

- Applications

-

High strength, high modulus, high temperature resistance, corrosion resistance, low density

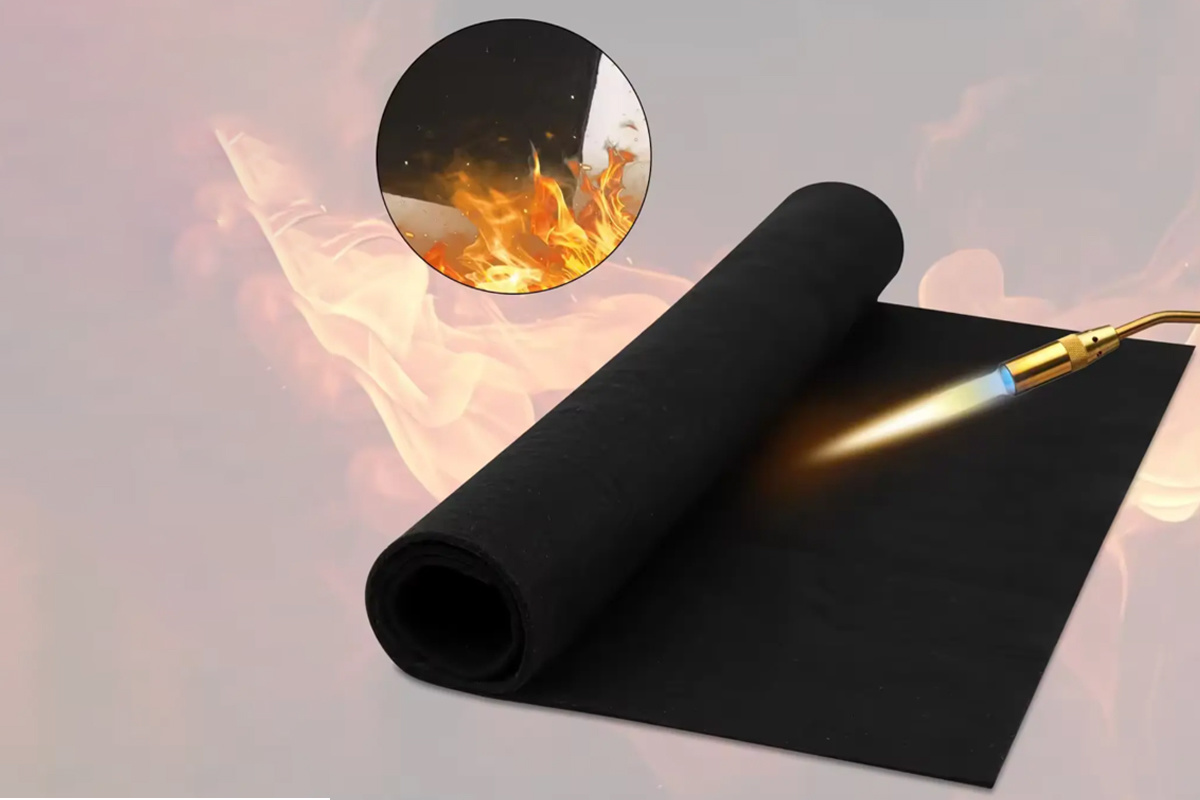

Aramid crimped fiber, as a high-performance material, maintains its structural integrity and stability even under tremendous external forces due to its high strength characteristics. It is an ideal choice for aerospace, automotive manufacturing, and other fields seeking ultimate safety and lightweight design. Its high modulus property means minimal deformation under stress, ensuring dimensional stability and application reliability. High temperature resistance allows aramid crimped fiber to function normally in extreme high-temperature environments without being affected by heat deformation or thermal degradation. This is crucial for industries such as fire-resistant clothing and high-temperature filter materials. Furthermore, its excellent corrosion resistance can withstand erosion from various chemicals, extending the material's service life and making it widely applicable in chemical and marine engineering fields. In addition, the low density of aramid crimped fiber significantly reduces product weight while maintaining performance, contributing to energy saving and emission reduction as well as improving overall performance. In summary, aramid crimped fiber plays an irreplaceable role in modern industrial and technological development due to its comprehensive advantages.

Advantages:(1) Non-melting

(2) Maintains high strength at high temperatures

(3) Good fatigue resistance and abrasion resistance

(4) Better vibration absorption than inorganic fibers

(5) Heat resistant

Disadvantages:(1) Poor compressibility

(2) Significant strength reduction and discoloration under UV irradiation -

(Curliness of 8-14)

Fineness/thickness is 1.5D and 2D (domestic) Foreign is 1.44 dtex and 2.22 dtex

Length is 38/51/65/76mm (the first two types can be made into felt, the latter two are mainly export products)

Felt made from crimped fibers is stronger and more durable than that made from short-cut fibers.

-

①Friction material;

②Sealing material (for solvent-based rubber sheets);

③Sealing material (for wet-laid paper);

④Specialty papermaking;

⑤Reinforced plastics, used in manufacturing automotive hoses, tires, timing belts, etc., especially in environmentally friendly turbocharged vehicles.

⑥Used in the preparation of fishing rods, golf clubs, tennis rackets, bows and arrows, sleds and other sporting goods.

⑦Aramid fibers can also be used as coated fabrics for air-supported structures and inflatable products, such as inflatable boats, life rafts, blimps, balloons, and special clothing.

⑧Aramid fibers are equally important in aerospace applications, used in manufacturing satellites, rocket engines, tire carcasses, brake pads, and other components.

⑨Military and police bulletproof vests, helmets, stab-resistant clothing, bomb disposal suits, high-strength parachutes, etc., also widely use aramid fibers.

Enterprise Advantages

Guangdong Kaidun New Materials Co., Ltd.

The layout of the entire workshop is reasonable, and the equipment is placed in an orderly manner, which not only ensures the smoothness of the production process but also improves work efficiency. Advanced production equipment and technologies are adopted in the workshop to ensure the stability of product quality and the efficiency of production efficiency.

In terms of the environment, the factory workshop effect picture shows a clean and bright production environment. The workshop is equipped with a good ventilation system and lighting equipment, providing comfortable working conditions for workers. At the same time, the workshop also pays attention to environmental protection and energy conservation, adopting environmentally friendly materials and energy-saving equipment to reduce energy consumption and pollution during the production process.

In terms of safety management, the factory workshop effect picture also reflects a high degree of attention. The workshop is equipped with complete safety facilities and warning signs to ensure the safety and health of workers during the production process. In addition, the workshop is also equipped with professional safety management personnel who are responsible for supervising and managing safety matters during the production process to ensure the safety and stability of production.

Production drawing of aramid filament woven fabric

Packaging and delivery of pre-oxidized fibers

Qualification Certification

Various qualification certifications obtained by Kaitun Industrial, demonstrating its professional capabilities in meeting standards in the field of high-performance fiber material textiles, highlighting that its products comply with strict quality, safety and industry regulatory requirements, providing strong support for the enterprise's stable development and market expansion.

Keyword:

Aramid crimped fiber

Aramid crimped fiber

Still deciding? Get samples first, Contact US !

Products Category

Inquire Now

We will contact you within one working day. Please pay attention to your email.

Related Products

Aramid silver-coated composite fabric