Share to

Polyimide Lifting Sling

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Features

- Specifications

- Applications

-

1. Excellent resistance to high and low temperatures

This is its most prominent feature. The long-term continuous use temperature range can reach up to -269°C to +260°C , the short-term temperature resistance peak can even exceed ** 400°C It neither becomes brittle at low temperatures nor melts at high temperatures (its glass transition temperature Tg typically exceeds 360°C), making its performance exceptionally stable.

2. Excellent electrical insulation performance

It possesses extremely high dielectric strength (breakdown voltage) and volume resistivity.

The dielectric constant and dielectric loss factor remain stable over a wide range of temperatures and frequencies.

Even in harsh environments such as high temperature and high humidity, it still maintains excellent insulation properties, making it the ideal insulating material for high-end electronics.

3. High mechanical strength and toughness

It exhibits excellent tensile and tear resistance, with mechanical strength far surpassing that of common materials such as PTFE (polytetrafluoroethylene) and silicone rubber.

It has excellent flexibility, making it easy to bend and install, and resistant to breakage.

4. Excellent chemical stability

It exhibits excellent resistance to most organic solvents, oils, acids, and weak bases, remaining resistant to swelling and degradation.

However, strong bases (such as concentrated sodium hydroxide) and prolonged exposure to high-temperature steam may affect it.

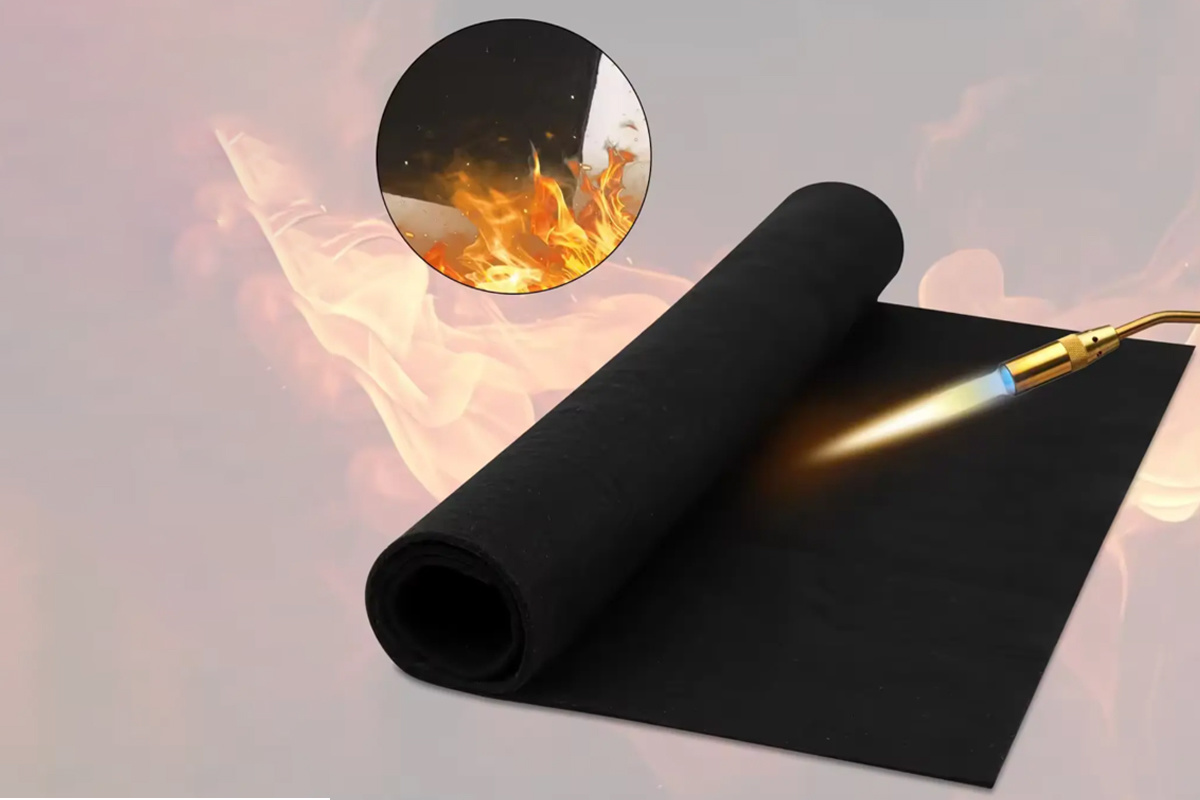

5. Flame-retardant and low-smoke, non-toxic

It inherently possesses flame retardancy, eliminating the need to add flame retardants.

When burned in flames, it produces extremely low smoke levels and emits no toxic or harmful gases, meeting the stringent safety requirements of industries such as aviation and high-speed rail.

6. Radiation Resistance

It exhibits high tolerance to ionizing radiation such as gamma rays and X-rays, with minimal performance degradation, making it suitable for applications in the nuclear industry and aerospace fields.

7. Low dielectric constant and low loss

This feature gives it an advantage in applications such as high-frequency communication and high-speed digital circuits, effectively reducing signal transmission loss and delay.

-

Multiple specifications available, customization supported.

-

1. Aerospace

Engine Area: purposefully designed to wrap and protect engine sensor harnesses and ignition system wires, while withstanding extreme temperatures and vibrations.

Within the organism: to be used for harness protection in flight control and avionics systems, it significantly enhances safety thanks to its lightweight and flame-retardant properties.

Satellites and Spacecraft: It is used to protect various cables from the extreme temperature fluctuations and cosmic radiation found in the space environment.

2. The automotive industry, especially new-energy vehicles

New energy vehicle motors: The flat wire windings encasing the motor interior, serving as turn-to-turn insulation, are a core application of corona-resistant polyimide tubing, capable of withstanding high-frequency pulse voltages and elevated temperatures.

Battery System: to be used for insulating and protecting the high-voltage wiring harness inside the battery pack, preventing short circuits and safeguarding against potentially severe temperatures during thermal runaway.

Traditional automobiles: to be used in high-temperature areas such as wiring harnesses near turbochargers and sensor wiring harnesses for brake systems.

3. Electronics and Electrical

Semiconductor Manufacturing: Cable protection used in high-temperature furnaces and plasma equipment.

High-temperature cable: As an insulating sleeve or outer sheath, it is used for connecting wires in equipment such as electric irons, heaters, and industrial electric furnaces.

PCB Board: Used as insulating or protective sleeves for electronic components.

4. Industrial Sector

Welding equipment: Protect the welding gun's cables and wires.

Heating equipment: For internal wiring of industrial heaters, ovens, and furnaces.

Special equipment: Used in demanding environments that require chemical resistance and radiation tolerance.

Enterprise Advantages

Guangdong Kaidun New Materials Co., Ltd.

The layout of the entire workshop is reasonable, and the equipment is placed in an orderly manner, which not only ensures the smoothness of the production process but also improves work efficiency. Advanced production equipment and technologies are adopted in the workshop to ensure the stability of product quality and the efficiency of production efficiency.

In terms of the environment, the factory workshop effect picture shows a clean and bright production environment. The workshop is equipped with a good ventilation system and lighting equipment, providing comfortable working conditions for workers. At the same time, the workshop also pays attention to environmental protection and energy conservation, adopting environmentally friendly materials and energy-saving equipment to reduce energy consumption and pollution during the production process.

In terms of safety management, the factory workshop effect picture also reflects a high degree of attention. The workshop is equipped with complete safety facilities and warning signs to ensure the safety and health of workers during the production process. In addition, the workshop is also equipped with professional safety management personnel who are responsible for supervising and managing safety matters during the production process to ensure the safety and stability of production.

Production drawing of aramid filament woven fabric

Packaging and delivery of pre-oxidized fibers

Qualification Certification

Various qualification certifications obtained by Kaitun Industrial, demonstrating its professional capabilities in meeting standards in the field of high-performance fiber material textiles, highlighting that its products comply with strict quality, safety and industry regulatory requirements, providing strong support for the enterprise's stable development and market expansion.

Keyword:

Polyimide Lifting Sling

Inquire Now

We will contact you within one working day. Please pay attention to your email.

Related Products

Aramid silver-coated composite fabric