Share to

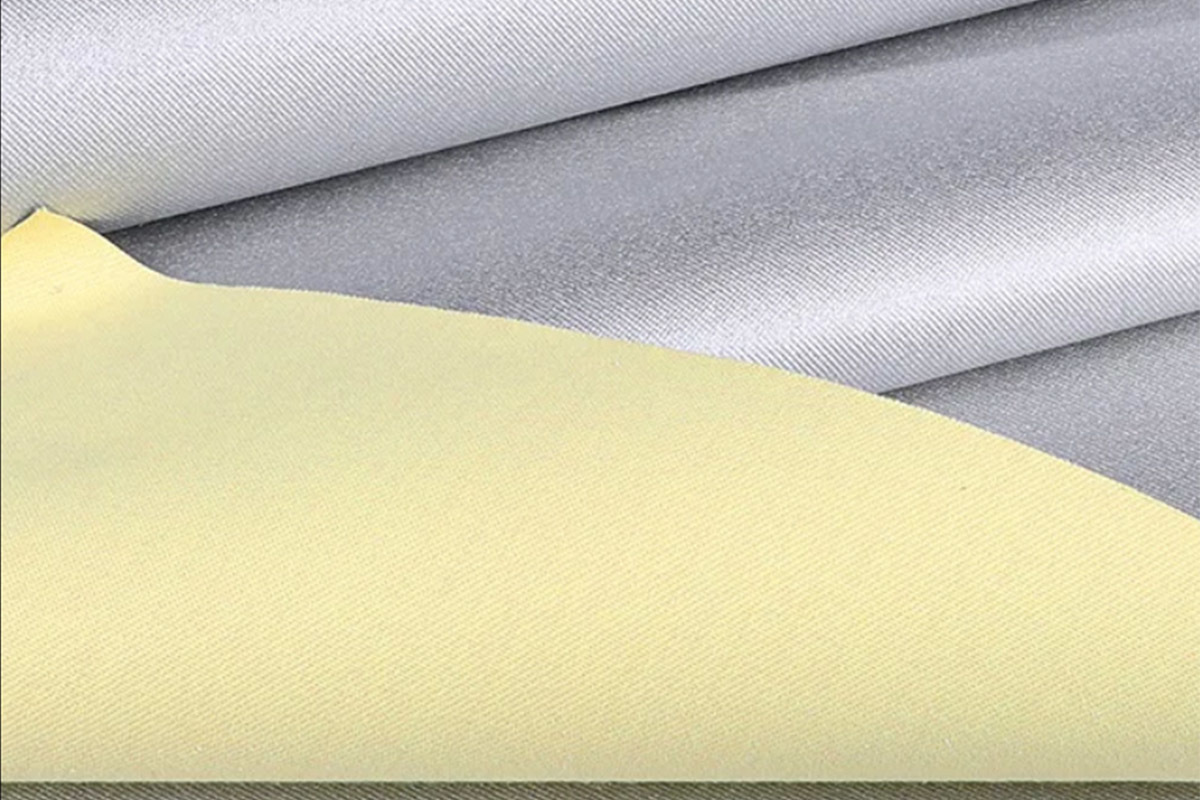

Polyimide Aramid Composite Base Fabric Felt

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Features

- Specifications

- Applications

-

1. Excellent temperature resistance. The benzene rings and nitrogen-containing five-membered heterocyclic structures in the polyimide fiber macromolecular chains significantly enhance intermolecular forces through the conjugation effect of aromatic heterocyclic structures and carbon-oxygen double bonds. This unique molecular structure endows the material with outstanding heat resistance, allowing it to operate stably in environments above 200°C for extended periods, with instantaneous temperature resistance exceeding 550°C, providing reliable assurance for high-temperature applications.

2. Outstanding mechanical properties. Para-aramid fibers are renowned for their excellent mechanical performance—they have a density only one-fifth that of steel plates, yet their tensile strength is more than five times that of steel plates. Aramid fibers have well-ordered molecular structures containing rigid crystalline units, which easily form liquid crystal phases. In the liquid crystal state, these rigid molecular chains arrange in a highly ordered parallel structure, imparting the material with excellent mechanical strength and dimensional stability.

3. Excellent chemical stability.

Polyimide fibers possess good chemical stability and can be used long-term in most organic solvent conditions, with alkali resistance superior to acid resistance. This characteristic enables the material to maintain stable performance in complex chemical environments, expanding its application range in corrosive environments.

4. Excellent filtration characteristics.

Polyimide fibers have irregular cross-sectional shapes and large specific surface areas, which significantly enhance their ability to capture dust particles and improve filtration efficiency. This feature makes them outstanding in the field of filtration and separation, especially suitable for capturing and processing fine dust.

-

Supports customization of various specifications and sizes.

-

Aramid polyimide blended composite base fabric felt, with its outstanding comprehensive performance, demonstrates broad application prospects in multiple industrial fields.

1. Industrial high-temperature filtration. In the treatment of high-temperature flue gas in industries such as cement, steel, and power generation, this material exhibits excellent performance. Especially in the treatment of cement kiln tail gas, it can withstand temperature fluctuations caused by operating conditions, avoiding the damage problems traditional filter materials face due to overheating.

2. Special protective equipment manufacturing. In the field of special protection, this material provides ideal solutions for firefighting suits, special protective gear, and industrial protective clothing. Its excellent heat resistance, flame retardancy, and comfort make it the preferred material for high-end protective equipment. Compared to traditional protective materials, it significantly improves wearing comfort and mobility while maintaining the same level of protection.

3. Aerospace and transportation. This material is used in thermal protection systems, cabin interior decoration, and equipment insulation. Its lightweight and high-strength characteristics meet the aerospace industry's requirements for weight reduction while complying with strict fire safety standards. In rail transportation, it is applied to train interiors, equipment compartment insulation, and fire isolation, ensuring operational safety.

4. New energy and electrical insulation. This material is used for thermal insulation protection of lithium battery packs and solar energy equipment. Its excellent electrical insulation performance and high-temperature resistance make it an ideal choice for electrical equipment insulation, especially demonstrating outstanding reliability in high-voltage and high-temperature environments.

5. Construction and safety protection. Applied in fire isolation for high-rise buildings, emergency escape route protection, and steel structure fire protection. Compared to traditional building materials, it offers advantages such as light weight, good fire resistance, and ease of construction, providing new solutions for modern building safety.

6. Environmental protection and energy recovery. This material is used for high-temperature gas filtration, harmful substance capture, and energy recovery systems. Its corrosion resistance and temperature resistance enable it to handle various industrial waste gases and pollutants, contributing to environmental protection and energy recovery.

Enterprise Advantages

Guangdong Kaidun New Materials Co., Ltd.

The layout of the entire workshop is reasonable, and the equipment is placed in an orderly manner, which not only ensures the smoothness of the production process but also improves work efficiency. Advanced production equipment and technologies are adopted in the workshop to ensure the stability of product quality and the efficiency of production efficiency.

In terms of the environment, the factory workshop effect picture shows a clean and bright production environment. The workshop is equipped with a good ventilation system and lighting equipment, providing comfortable working conditions for workers. At the same time, the workshop also pays attention to environmental protection and energy conservation, adopting environmentally friendly materials and energy-saving equipment to reduce energy consumption and pollution during the production process.

In terms of safety management, the factory workshop effect picture also reflects a high degree of attention. The workshop is equipped with complete safety facilities and warning signs to ensure the safety and health of workers during the production process. In addition, the workshop is also equipped with professional safety management personnel who are responsible for supervising and managing safety matters during the production process to ensure the safety and stability of production.

Production drawing of aramid filament woven fabric

Packaging and delivery of pre-oxidized fibers

Qualification Certification

Various qualification certifications obtained by Kaitun Industrial, demonstrating its professional capabilities in meeting standards in the field of high-performance fiber material textiles, highlighting that its products comply with strict quality, safety and industry regulatory requirements, providing strong support for the enterprise's stable development and market expansion.

Keyword:

Polyimide Aramid Composite Base Fabric Felt

Polyimide Aramid Composite Base Fabric Felt

Still deciding? Get samples first, Contact US !

Products Category

Inquire Now

We will contact you within one working day. Please pay attention to your email.

Related Products

Aramid silver-coated composite fabric