Share to

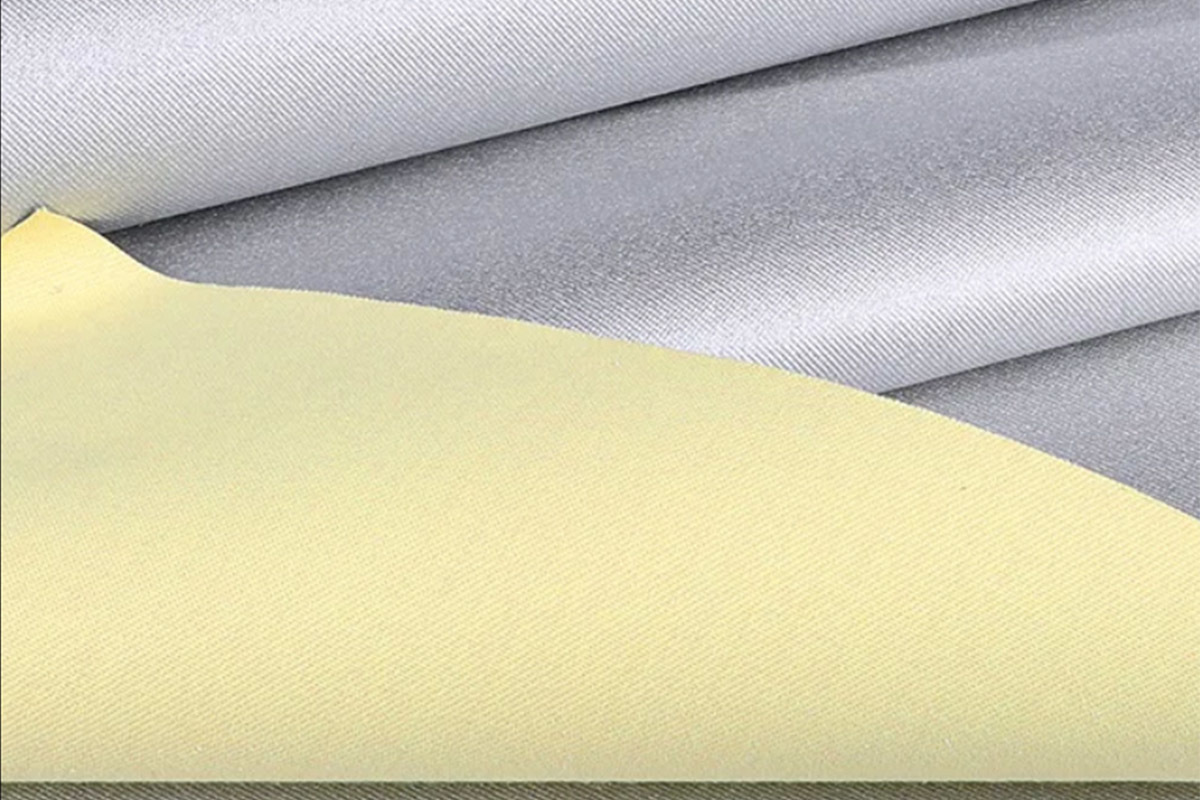

Polyimide pre-oxidized silk blended composite fabric

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Features

- Specifications

- Applications

-

Thermal Stability and Flame Retardancy

High-Temperature Resistance Polyimide fiber has long-term temperature resistance up to 260℃ and instantaneous temperature resistance exceeding 300℃; pre-oxidized fiber has temperature resistance ≥400℃. After the two are combined, the base fabric can maintain structural stability in high-temperature environments, with a strength retention rate >90% (300℃).

Inherently Flame Retardant Polyimide has a limiting oxygen index (LOI) as high as 44, and pre-oxidized fiber LOI >45. After blending, the base fabric is self-extinguishing and drip-free after removing the flame, only carbonizing during combustion with extremely low smoke density, meeting the high safety requirements of aviation, fire protection, etc.

Excellent Mechanical Properties

High Strength and Abrasion Resistance Polyimide fiber has a tensile strength of 4.0 GPa and a modulus of 160 GPa; pre-oxidized fiber has high modulus and creep resistance. After compounding, the tear resistance and puncture resistance of the base fabric are significantly improved, suitable for high-wear scenarios.

Flexible and Lightweight Density 1.41 g/cm³, can be cut and sewn into complex shapes, more than 30% lighter than metal, suitable for lightweight design in aerospace.

Chemical and Environmental Stability

Corrosion Resistance Stable against weak acids, weak alkalis, organic solvents, and oils, suitable for corrosive environments such as garbage incineration and chemical filtration.

Anti-UV Aging Composite coatings (such as nano-titanium oxide) can absorb ultraviolet rays and extend the outdoor service life.

Functional Designability

Surface Modification Plasma treatment can impart hydrophilicity (contact angle reduced from 121.5° to 68.5°) or antibacterial properties (E. coli inhibition rate >64%).

Electromagnetic Shielding Combined with metallized coatings (such as aluminum foil), an electromagnetic wave shielding rate of >95% can be achieved. [The above data are from the internet and laboratory]

-

Customization supported.

-

High-temperature industrial filtration

Flue gas dust removal :Used for garbage incinerator and cement kiln tail gas filtration, resistant to 260℃ acidic dust.

Chemical filtration :Corrosion-resistant properties are suitable for acid and alkali gas filtration, extending the filter bag replacement cycle by more than 3 times.

Special protective equipment

Firefighting and military defense :Blended yarn is used to make fire suits and armored soldier protective suits, combining flame retardancy, heat insulation, and cut resistance (such as pre-oxidized yarn/flame-retardant nylon/polyimide blended yarn).

Bio-chemical protection :After antibacterial modification, it is used for gas masks and medical protective clothing to block the spread of pathogens.

New energy and high-temperature insulation

Battery thermal protection :As a heat insulation layer for lithium battery packs, it prevents the spread of thermal runaway.

Pipeline insulation :Aramid 1313/pre-oxidized yarn composite structure, reducing heat loss in industrial heat transfer pipelines by >40%.

Aerospace and transportation

Aircraft interiors :Aircraft seat covers, engine compartment heat insulation layers.

High-speed rail materials :Lightweight car body lining, with both sound insulation and fire prevention functions.

Electronics and insulation materials

High insulation substrate :Low water absorption rate (<1%) and dielectric constant (3.0~3.5), used for motor slot insulation and chip packaging.

Enterprise Advantages

Guangdong Kaidun New Materials Co., Ltd.

The layout of the entire workshop is reasonable, and the equipment is placed in an orderly manner, which not only ensures the smoothness of the production process but also improves work efficiency. Advanced production equipment and technologies are adopted in the workshop to ensure the stability of product quality and the efficiency of production efficiency.

In terms of the environment, the factory workshop effect picture shows a clean and bright production environment. The workshop is equipped with a good ventilation system and lighting equipment, providing comfortable working conditions for workers. At the same time, the workshop also pays attention to environmental protection and energy conservation, adopting environmentally friendly materials and energy-saving equipment to reduce energy consumption and pollution during the production process.

In terms of safety management, the factory workshop effect picture also reflects a high degree of attention. The workshop is equipped with complete safety facilities and warning signs to ensure the safety and health of workers during the production process. In addition, the workshop is also equipped with professional safety management personnel who are responsible for supervising and managing safety matters during the production process to ensure the safety and stability of production.

Production drawing of aramid filament woven fabric

Packaging and delivery of pre-oxidized fibers

Qualification Certification

Various qualification certifications obtained by Kaitun Industrial, demonstrating its professional capabilities in meeting standards in the field of high-performance fiber material textiles, highlighting that its products comply with strict quality, safety and industry regulatory requirements, providing strong support for the enterprise's stable development and market expansion.

Keyword:

Polyimide pre-oxidized silk blended composite fabric

Polyimide pre-oxidized silk blended composite fabric

Still deciding? Get samples first, Contact US !

Products Category

Inquire Now

We will contact you within one working day. Please pay attention to your email.

Related Products

Aramid silver-coated composite fabric