Share to

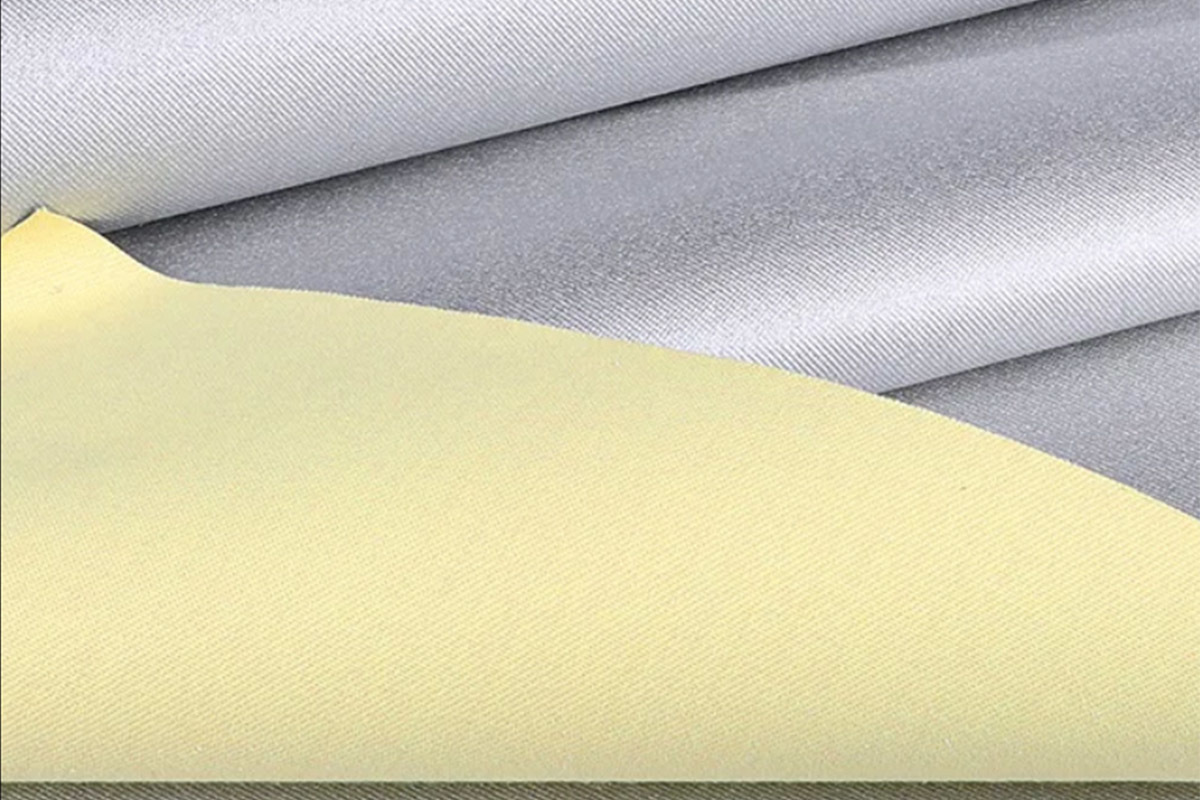

PBO fiber braided tape

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Features

- Specifications

- Applications

-

Mechanical Properties

Ultra-High Strength and Modulus Tensile strength reaches 5.8 GPa, modulus up to 270–280 GPa, specific strength is 12–14 times that of steel, and specific modulus far exceeds carbon fiber and aramid. A 1mm diameter PBO monofilament can withstand approximately 450kg.

Excellent Impact Resistance Energy absorption capacity is significantly higher than carbon fiber composite materials, suitable for bulletproof and impact-resistant scenarios.

Heat Resistance and Flame Retardancy

High Temperature Stability Thermal decomposition temperature reaches 650℃, long-term use temperature exceeds 350℃, approximately 100℃ higher than para-aramid.

Limiting Oxygen Index (LOI) is 68% It does not burn or shrink when in contact with flames; it only carbonizes.

Environmental Adaptability

Chemical Inertness Resistant to acid, alkali, and organic solvent corrosion; suitable for harsh environments such as chemical filtration.

Excellent Wave Transparency Transmittance >98%, does not interfere with high-frequency signals such as 5G, and is suitable for electronic device structural components.

Low Density (1.54–1.56 g/cm³): Outstanding lightweight advantage, approximately 20% lighter than carbon fiber.

Functional Limitations

Poor UV Resistance After 40 hours of UV irradiation, the strength retention rate is only 37% (aramid is 80%), requiring surface coating modification (such as TiO₂/ZnO composite sol or alicyclic epoxy resin coating).

Weak Interface Bonding The surface is smooth and highly inert, with low adhesion to the resin matrix; plasma treatment or nanofiber coating (such as PAN electrospinning) is required to enhance the composite interface.

-

1. Aerospace and Special Equipment

Spacecraft Components Used for rocket engine thermal insulation layers, fuel tanks, space wiring systems, and deep-space exploration balloons (such as those used in Venus exploration missions, withstanding temperature variations from -10℃ to 460℃).

Armor Protection Used in woven bulletproof vests, helmets, and armor plates, providing lightweight protection against large-caliber bullets; structural reinforcement components for missile tactical equipment.

Lightweight Equipment Reduces the weight of aircraft and drone structures, improving maneuverability and payload capacity.

2. Safety Protection and Special Industries

Firefighting and High-Temperature Work Clothing Flame-retardant woven straps used in firefighting suits, welding suits, and molten metal handling work clothes, ensuring safety in extreme heat environments.

Live-Line Work Tools Modified and woven into extra-high voltage insulating ropes, combining high tensile strength (>1000kV), lasting moisture resistance, and insulation.

Industrial Consumables High-temperature filter bags (dust removal in cement and metallurgical industries), optical fiber reinforcing cores (reducing diameter and noise), and heat-resistant sealing gaskets.

3. Consumer Electronics and High-End Equipment

Folding Screen Phone Structural Components Used as a backplane reinforcement material, reducing thickness by half without signal shielding, supporting ultra-thin designs.

Sporting Goods Tennis racket frames, bicycle spokes, racing boat sails, fishing rods, etc., providing high rigidity and shock absorption.

4. Emerging Field Expansion

New Energy and Electronics Lithium battery separators (high-temperature safety), flexible sensor substrates (nanofiber form).

Building Reinforcement Woven straps for earthquake-resistant cement components, improving crack resistance and toughness.

Enterprise Advantages

Guangdong Kaidun New Materials Co., Ltd.

The layout of the entire workshop is reasonable, and the equipment is placed in an orderly manner, which not only ensures the smoothness of the production process but also improves work efficiency. Advanced production equipment and technologies are adopted in the workshop to ensure the stability of product quality and the efficiency of production efficiency.

In terms of the environment, the factory workshop effect picture shows a clean and bright production environment. The workshop is equipped with a good ventilation system and lighting equipment, providing comfortable working conditions for workers. At the same time, the workshop also pays attention to environmental protection and energy conservation, adopting environmentally friendly materials and energy-saving equipment to reduce energy consumption and pollution during the production process.

In terms of safety management, the factory workshop effect picture also reflects a high degree of attention. The workshop is equipped with complete safety facilities and warning signs to ensure the safety and health of workers during the production process. In addition, the workshop is also equipped with professional safety management personnel who are responsible for supervising and managing safety matters during the production process to ensure the safety and stability of production.

Production drawing of aramid filament woven fabric

Packaging and delivery of pre-oxidized fibers

Qualification Certification

Various qualification certifications obtained by Kaitun Industrial, demonstrating its professional capabilities in meeting standards in the field of high-performance fiber material textiles, highlighting that its products comply with strict quality, safety and industry regulatory requirements, providing strong support for the enterprise's stable development and market expansion.

Keyword:

PBO fiber braided tape

Inquire Now

We will contact you within one working day. Please pay attention to your email.

Related Products

Aramid silver-coated composite fabric