Share to

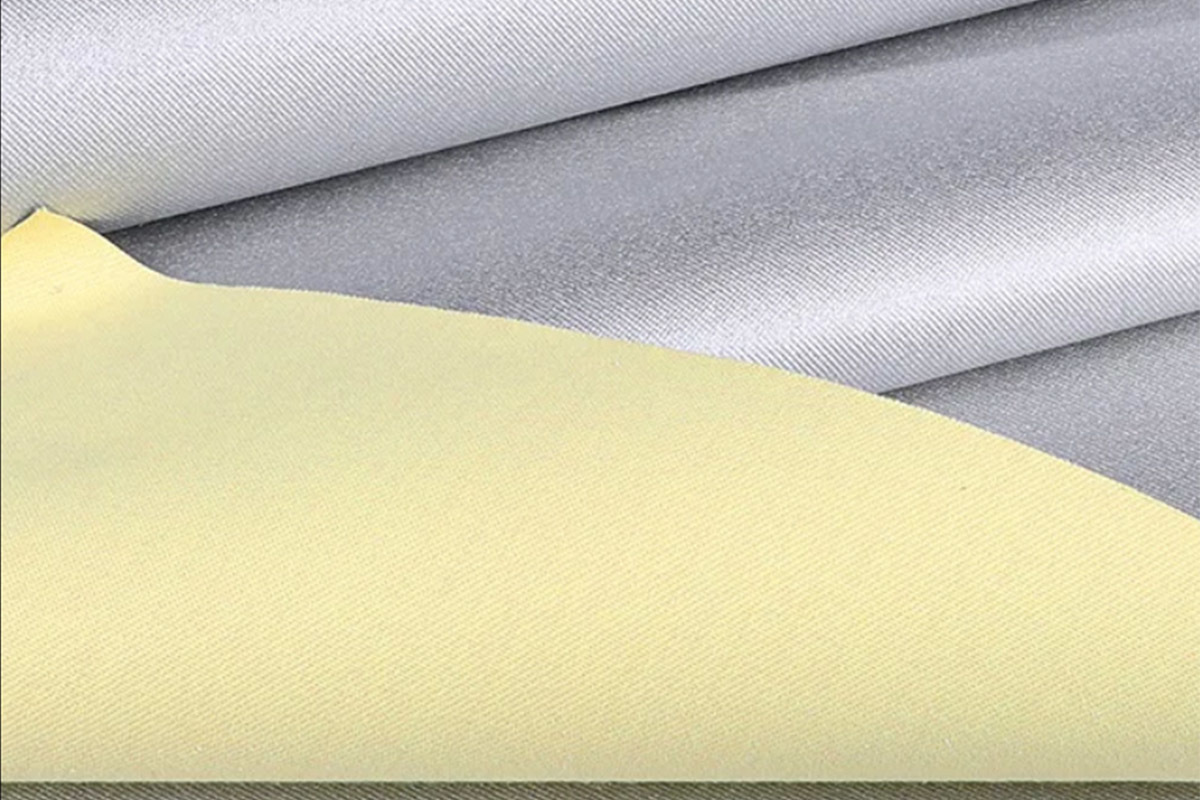

Pre-oxidized para-aramid/polyester blended woven fabric

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Features

- Specifications

- Applications

-

High-temperature protection performance

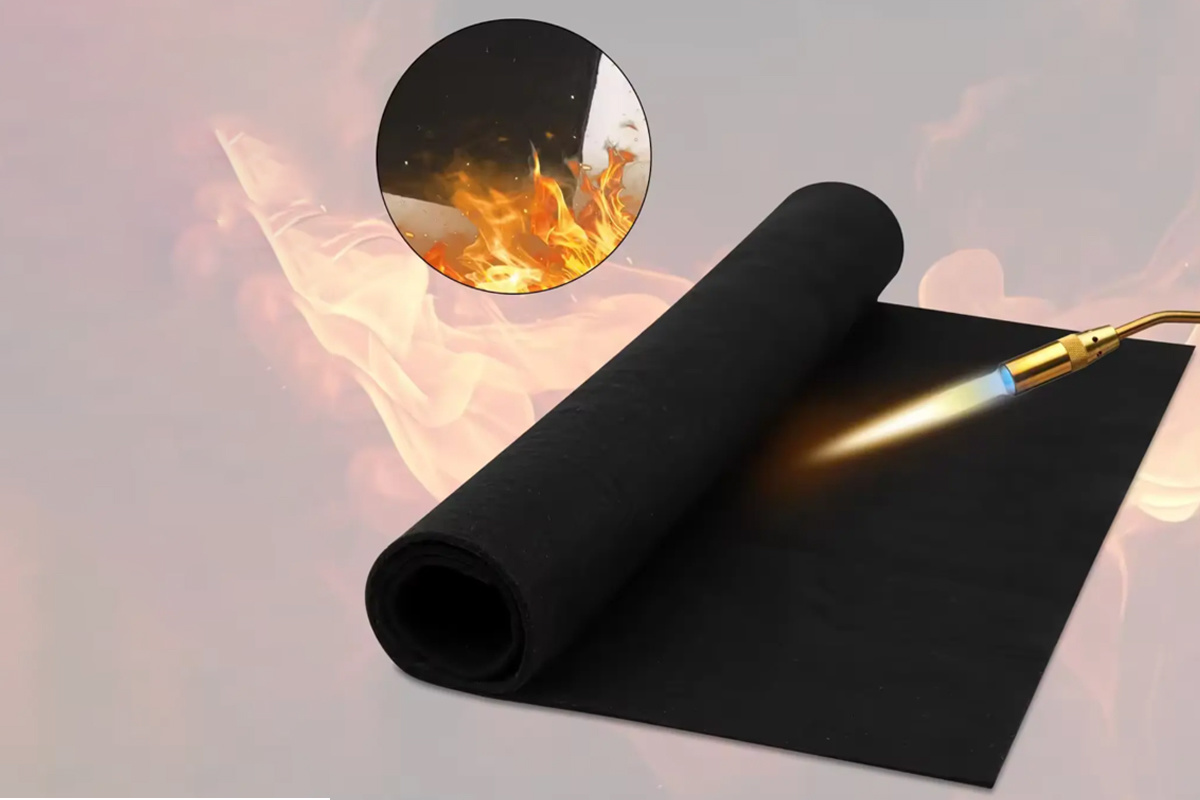

Flame retardancy :The pre-oxidized fiber has a limiting oxygen index (LOI) of 40~60, and a decomposition temperature ≥640℃; the thermal decomposition temperature of aramid (such as para-aramid 1414) is >430℃. After blending, the limiting oxygen index is significantly higher than that of pure aramid. When burning, a carbonized layer is formed to isolate oxygen, achieving "non-melting, no dripping".

Heat insulation :Pre-oxidized fiber has low thermal conductivity (0.047~0.056 W/(m·K)), and aramid has stable high-temperature resistance. The blended fabric maintains its structural integrity at high temperatures and is suitable for instantaneous high-temperature environments (such as firefighter uniforms).

Mechanical properties and wearability

Strength and wear resistance :Aramid compensates for the low strength (1.4 cN/dtex) and brittleness of pre-oxidized fiber. After blending, the yarn strength is increased by more than 30%, and the wear resistance is close to that of pure nylon (the best textile fiber).

Comfort :The moisture regain of pre-oxidized fiber is 9%, and aramid has poor moisture absorption, but the breathability and perspiration performance can be improved by adjusting the blending ratio (such as adding flame-retardant viscose), reducing the stuffiness of protective clothing.

Thermal stability and durability

The blended fabric maintains its strength at 240℃ for long-term use and begins to carbonize at 400℃; the thermal shrinkage rate is <3% (pure pre-oxidized fiber felt >10%), and it maintains dimensional stability after repeated high-temperature exposure.

Excellent chemical corrosion resistance, resistant to acid, alkali, and organic solvent corrosion, suitable for industrial environments.

Diverse structural design

Supports aramid/pre-oxidized fiber blending ratios such as 40/60, 50/50, and 30/70, with a weight range of 200~350 g/m², and can be covered with aluminum foil to enhance reflective heat insulation performance.

-

Customization supported.

-

Special Protective Equipment

Firefighting Suits :The outer layer uses blended woven fabric (such as 35% pre-oxidized fiber + 60% PPS + 5% flame-retardant acrylic fiber), with a damage length of only 23 mm (pure aramid felt 72 mm), combining lightness and heat insulation.

Industrial Thermal Protective Clothing :Steelmaking and welding work clothes utilize their resistance to flying sparks. After being coated with aluminum foil, they reflect thermal radiation and reduce the surface temperature.

High-Temperature Industrial Fields

Insulation Materials :Used for the insulation layer of pipelines and high-temperature furnaces (260~880℃), replacing asbestos, with no carcinogenic risk and foldable construction.

Flame-Retardant Padding :Non-woven fabric form used in aircraft and high-speed rail interiors.

Transportation Interior Decoration

Aviation seat covers and maglev train interiors have passed vertical combustion tests, with low smoke density and no molten drops, ensuring fire escape safety.

Innovative Application Directions

Composite Reinforced Materials :Multi-layer composite design (pre-oxidized fiber + modified cotton + aramid), after coating with a flame-retardant coating, it is used for special armor lining.

Environmental Remediation Materials :Pre-oxidized fiber-based non-woven fabric is used as an isolation layer for the remediation of heavy metal-contaminated soil, which is corrosion-resistant and long-lasting.

Enterprise Advantages

Guangdong Kaidun New Materials Co., Ltd.

The layout of the entire workshop is reasonable, and the equipment is placed in an orderly manner, which not only ensures the smoothness of the production process but also improves work efficiency. Advanced production equipment and technologies are adopted in the workshop to ensure the stability of product quality and the efficiency of production efficiency.

In terms of the environment, the factory workshop effect picture shows a clean and bright production environment. The workshop is equipped with a good ventilation system and lighting equipment, providing comfortable working conditions for workers. At the same time, the workshop also pays attention to environmental protection and energy conservation, adopting environmentally friendly materials and energy-saving equipment to reduce energy consumption and pollution during the production process.

In terms of safety management, the factory workshop effect picture also reflects a high degree of attention. The workshop is equipped with complete safety facilities and warning signs to ensure the safety and health of workers during the production process. In addition, the workshop is also equipped with professional safety management personnel who are responsible for supervising and managing safety matters during the production process to ensure the safety and stability of production.

Production drawing of aramid filament woven fabric

Packaging and delivery of pre-oxidized fibers

Qualification Certification

Various qualification certifications obtained by Kaitun Industrial, demonstrating its professional capabilities in meeting standards in the field of high-performance fiber material textiles, highlighting that its products comply with strict quality, safety and industry regulatory requirements, providing strong support for the enterprise's stable development and market expansion.

Keyword:

Pre-oxidized para-aramid/polyester blended woven fabric

Pre-oxidized para-aramid/polyester blended woven fabric

Still deciding? Get samples first, Contact US !

Products Category

Inquire Now

We will contact you within one working day. Please pay attention to your email.

Related Products

Aramid silver-coated composite fabric