Share to

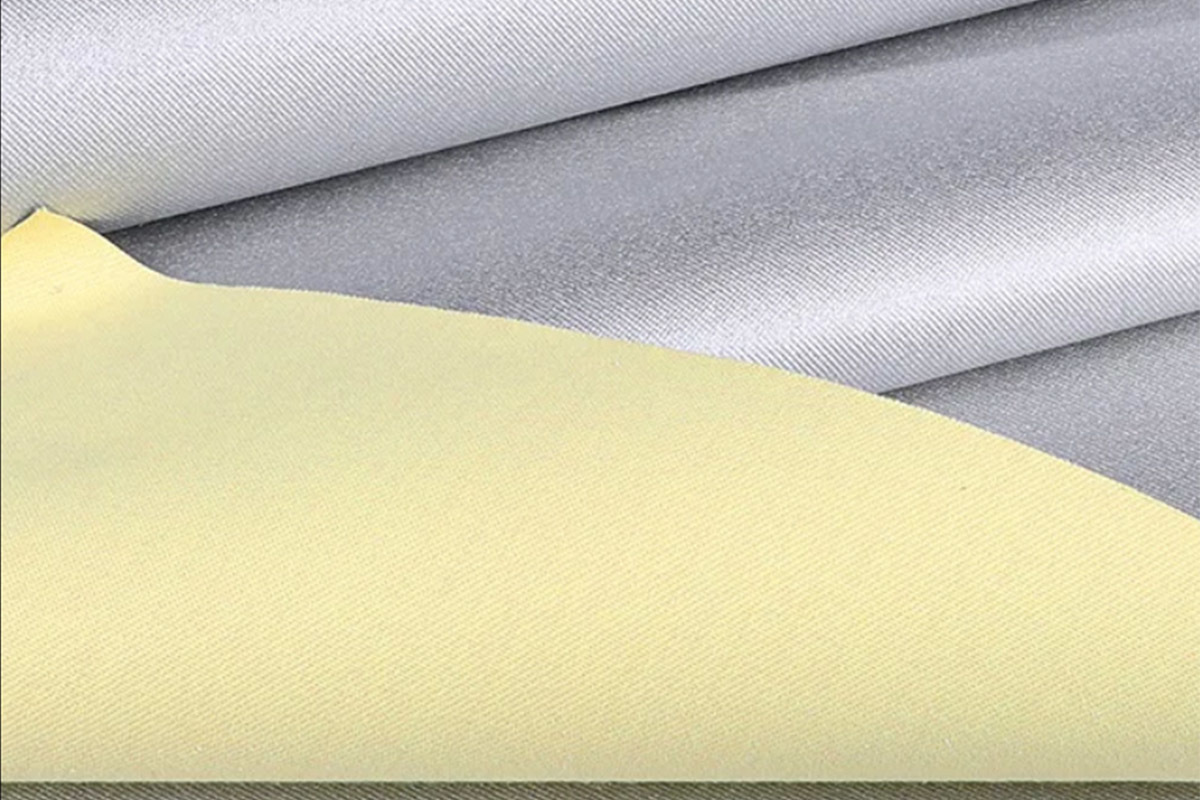

Hydroentangled polyimide nonwovens

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Features

- Specifications

- Applications

-

Excellent Physical and Mechanical Properties

High Strength and Durability :After hydroentanglement, the breaking strength of polyimide fibers in both warp and weft directions is significantly improved (for example, the warp breaking strength of 100 g/m² specification reaches 448 N, and the weft breaking strength is 102 N). The flexible entanglement process does not damage the fiber structure itself, maintaining high resilience and tear resistance.

Extreme Temperature Resistance :It can be used stably in the range of -200°C to 300°C without embrittlement or softening, suitable for high-temperature or low-temperature environments.

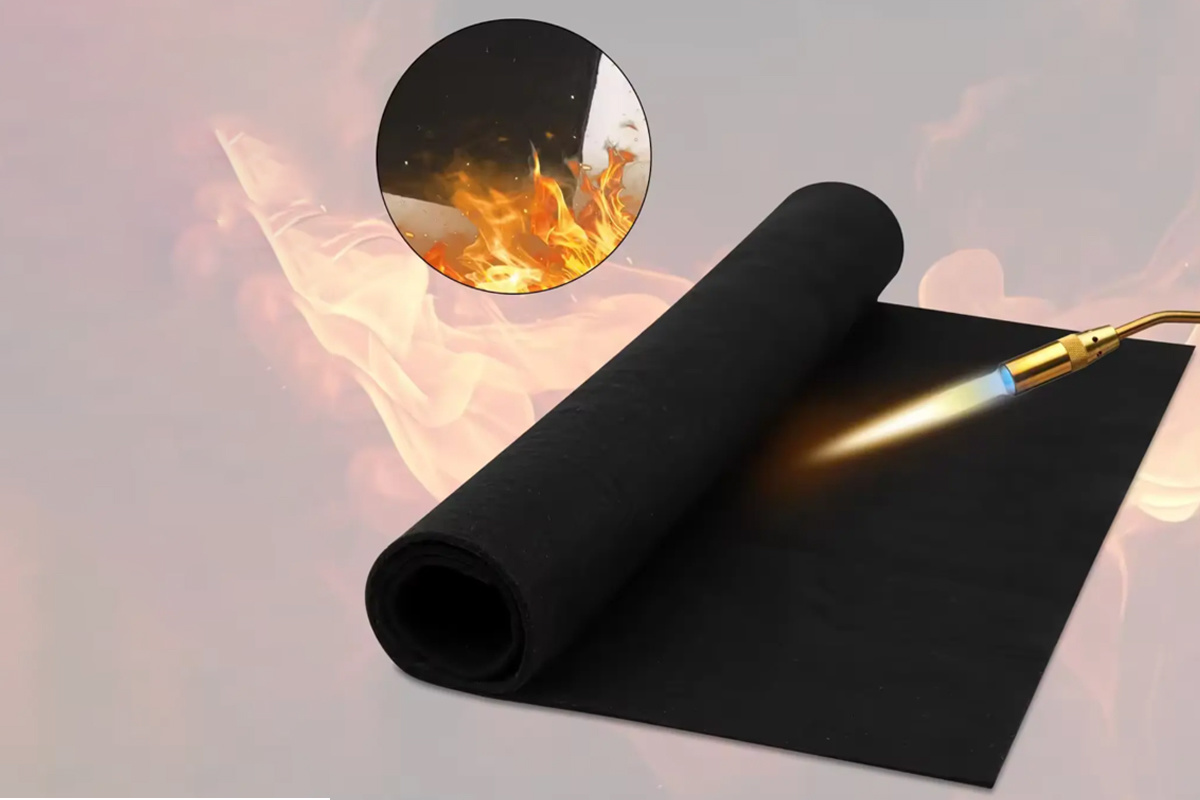

Top-Level Flame Retardant Performance

The limiting oxygen index (LOI) is >30%. When encountering fire, there is no melting, no smoldering, and the damage length is <2 mm, far exceeding ordinary flame-retardant materials.

Excellent Chemical Stability

Resistant to strong acids (30% HCl, 40% HNO₃), strong alkalis (20% NaOH), and organic solvents. The mechanical property attenuation rate is <10% after immersion, suitable for chemical protection scenarios.

Comfort and Design Flexibility

Skin-Friendly and Antibacterial :Plasma treatment can significantly improve surface hydrophilicity (contact angle reduced from 121.5° to 68.5°) and impart antibacterial properties (64.3% inhibition rate against Escherichia coli, 91.6% against Staphylococcus aureus).

Breathable and Moisture-Permeable :The three-dimensional network structure of the fiber provides high breathability (>1000 L/m²/s) and has moisture-wicking and quick-drying properties.

-

Customization supported.

Basis weight: 70g, width: 1.5m.

-

High-end protective equipment

Chemical protective suit :As a skeleton layer material, used in Class A chemical protective suits, combining flame retardancy, corrosion resistance, and lightweight properties (such as fire fighting and nuclear industry).

Special filter material :Combined with electrostatic electret technology, it is made into a high-efficiency filter layer for filtering high-temperature flue gas or chemical dust (PM0.3 filtration efficiency >99.9%).

Medical and hygiene materials

Functional dressings and surgical gowns :Utilizing its antibacterial and hypoallergenic properties, it is used for wound dressings (promoting serine absorption to accelerate healing) and surgical isolation layers.

Microecological balance hygiene products :Treated with functional auxiliaries such as chitosan/octanoylhydroxamic acid, it can regulate skin flora and is used in high-end sanitary napkins, wet wipes, etc.

Industrial precision field

Aviation/electronic wipes :High liquid absorbency (penetration increased by 181.9%) and low reverse osmosis characteristics, cleaning precision instruments without leaving residual fibers.

High-temperature sealing and insulation materials :As a composite reinforcement layer, used in engine heat shields or battery fireproof diaphragms.

Advanced composite materials

Multi-component functional composite :For example, a three-layer structure of "flame retardant-antibacterial-filtration" (PI flame retardant surface layer, antibacterial double-component fiber in the middle, and electrostatic electret polyester bottom layer) achieves multi-functional integration.

Bionic structural design :Such as peach-skin-like finishing (brushing + nano PU coating), improving the feel and fit of the garment base fabric.

Enterprise Advantages

Guangdong Kaidun New Materials Co., Ltd.

The layout of the entire workshop is reasonable, and the equipment is placed in an orderly manner, which not only ensures the smoothness of the production process but also improves work efficiency. Advanced production equipment and technologies are adopted in the workshop to ensure the stability of product quality and the efficiency of production efficiency.

In terms of the environment, the factory workshop effect picture shows a clean and bright production environment. The workshop is equipped with a good ventilation system and lighting equipment, providing comfortable working conditions for workers. At the same time, the workshop also pays attention to environmental protection and energy conservation, adopting environmentally friendly materials and energy-saving equipment to reduce energy consumption and pollution during the production process.

In terms of safety management, the factory workshop effect picture also reflects a high degree of attention. The workshop is equipped with complete safety facilities and warning signs to ensure the safety and health of workers during the production process. In addition, the workshop is also equipped with professional safety management personnel who are responsible for supervising and managing safety matters during the production process to ensure the safety and stability of production.

Production drawing of aramid filament woven fabric

Packaging and delivery of pre-oxidized fibers

Qualification Certification

Various qualification certifications obtained by Kaitun Industrial, demonstrating its professional capabilities in meeting standards in the field of high-performance fiber material textiles, highlighting that its products comply with strict quality, safety and industry regulatory requirements, providing strong support for the enterprise's stable development and market expansion.

Keyword:

Hydroentangled polyimide nonwovens

Hydroentangled polyimide nonwovens

Still deciding? Get samples first, Contact US !

Products Category

Inquire Now

We will contact you within one working day. Please pay attention to your email.

Related Products

Aramid silver-coated composite fabric