Share to

- Features

- Specifications

- Applications

-

Temperature Stability

High-Temperature Resistance :Long-term use temperature can reach 300°C or higher (Some models can withstand 400°C for short periods), no melting or decomposition at high temperatures.

Low-Temperature Resistance :At -200°C It remains flexible in cryogenic environments, with no risk of cracking.

(In contrast: The operating temperature of ordinary polyurethane foam is usually below 120°C)Ultralight and High Specific Strength

Extremely low density ( 0.01–0.1 g/cm³ ), close to air, but with a certain compressive strength, suitable for lightweight applications.

Excellent Thermal and Acoustic Insulation Performance

The closed-cell structure effectively blocks heat conduction (thermal conductivity 0.03–0.05 W/(m·K) ), and also has sound absorption and noise reduction functions.

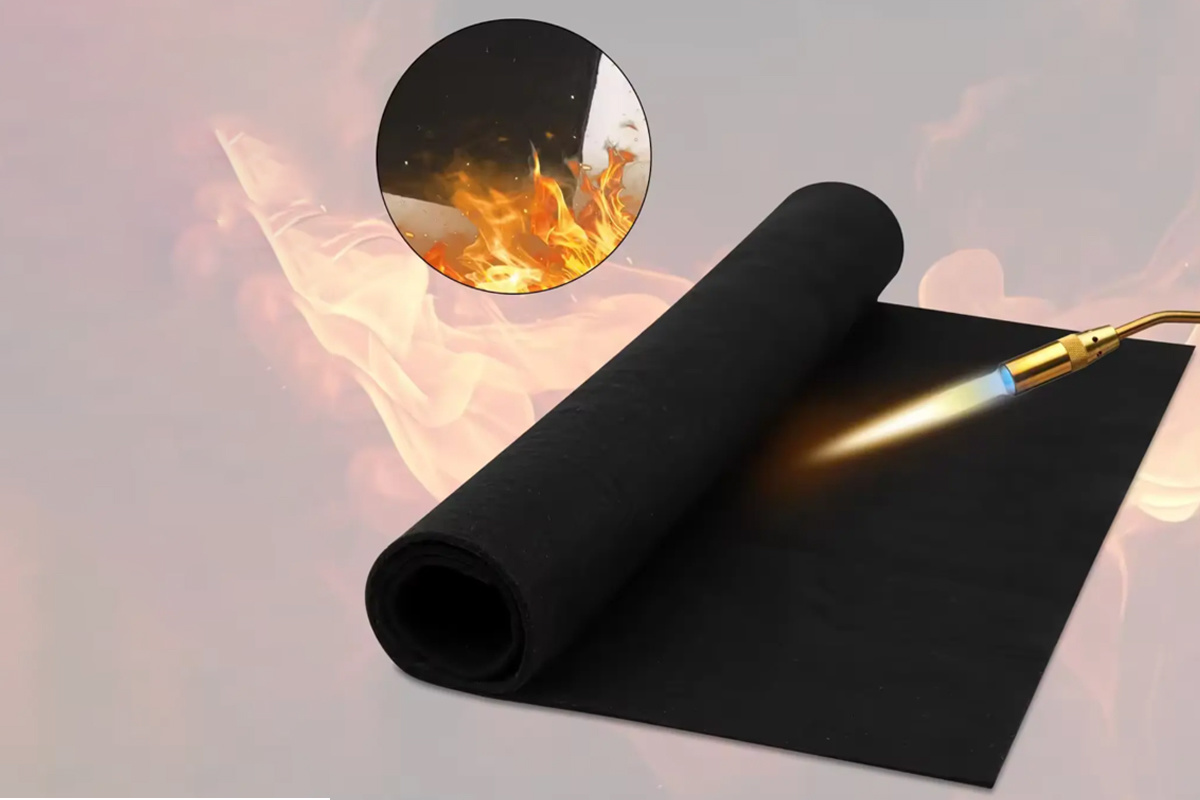

Flame Retardant and Low Toxicity

Limiting Oxygen Index (LOI) > 40% far exceeds the flame retardant standard (UL94 V-0 level), produces almost no toxic fumes at high temperatures meets the stringent requirements of aircraft interiors.

Chemical and Radiation Stability

Resistant to solvents, fuels, hydraulic oils, and most acids and alkalis, resistant to ultraviolet and γ-ray radiation, suitable for space environments.

Low Outgassing

Very little volatiles in a vacuum environment, avoiding contamination of precision optical instruments, meeting the standards for spacecraft materials

-

Customization supported.

-

1. Aerospace

Thermal Insulation System :Fire-resistant partitions for aircraft engine compartments, insulation layers for cryogenic fuel tanks (liquid hydrogen/liquid oxygen) in rockets.

Lightweight Structure :Satellite honeycomb core filling, heat insulation and weight reduction for spacecraft walls.

Noise Reduction Material :Sound-absorbing layers for cabin interiors (e.g., some models of Airbus A380).

2. Electronics and Semiconductors

Chip Manufacturing :Thermal shielding for wafer processing equipment (high-temperature clean environment).

High-Frequency Circuits :5G base station antenna covers (low dielectric constant, low signal loss).

3. Transportation

High-speed Rail/Ships :Fire-resistant compartment filling, pipeline insulation.

New Energy Vehicles :Thermal runaway protection layer for battery packs (flame retardant and fireproof).

4. Industry and Energy

LNG Storage and Transportation :Ultra-low temperature pipeline insulation materials (-162°C operating conditions).

Nuclear Power Facilities :Radiation protection filling around the reactor.

5. Special Protection

Fire Suit Insulation Layer :Replaces traditional asbestos, combining lightweight and safety features.

Military Equipment :Fireproof armor for warships, insulation boxes for field equipment.

Enterprise Advantages

Guangdong Kaidun New Materials Co., Ltd.

The layout of the entire workshop is reasonable, and the equipment is placed in an orderly manner, which not only ensures the smoothness of the production process but also improves work efficiency. Advanced production equipment and technologies are adopted in the workshop to ensure the stability of product quality and the efficiency of production efficiency.

In terms of the environment, the factory workshop effect picture shows a clean and bright production environment. The workshop is equipped with a good ventilation system and lighting equipment, providing comfortable working conditions for workers. At the same time, the workshop also pays attention to environmental protection and energy conservation, adopting environmentally friendly materials and energy-saving equipment to reduce energy consumption and pollution during the production process.

In terms of safety management, the factory workshop effect picture also reflects a high degree of attention. The workshop is equipped with complete safety facilities and warning signs to ensure the safety and health of workers during the production process. In addition, the workshop is also equipped with professional safety management personnel who are responsible for supervising and managing safety matters during the production process to ensure the safety and stability of production.

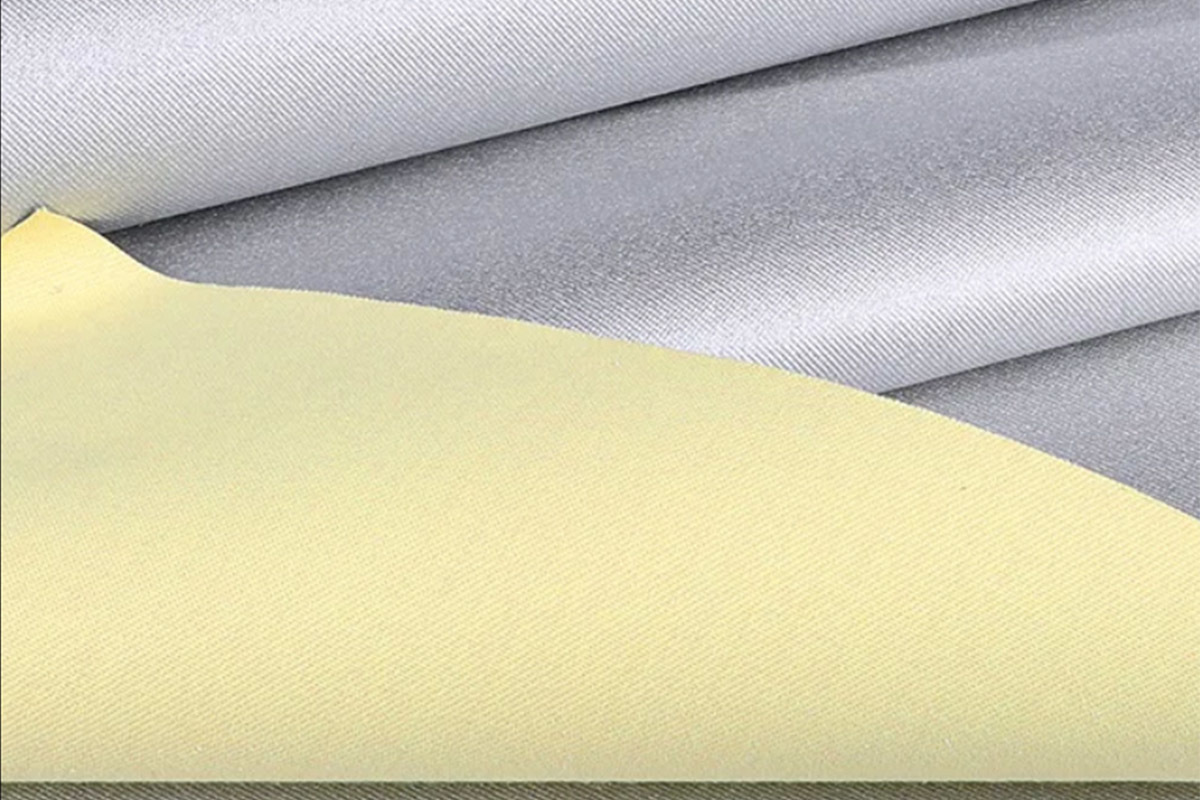

Production drawing of aramid filament woven fabric

Packaging and delivery of pre-oxidized fibers

Qualification Certification

Various qualification certifications obtained by Kaitun Industrial, demonstrating its professional capabilities in meeting standards in the field of high-performance fiber material textiles, highlighting that its products comply with strict quality, safety and industry regulatory requirements, providing strong support for the enterprise's stable development and market expansion.

Keyword:

Polyimide foam

Inquire Now

We will contact you within one working day. Please pay attention to your email.

Related Products

Aramid silver-coated composite fabric