Share to

Ultra-high molecular weight polyethylene sewing thread

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Features

- Specifications

- Applications

-

Ultra-High Molecular Weight Polyethylene Sewing Thread

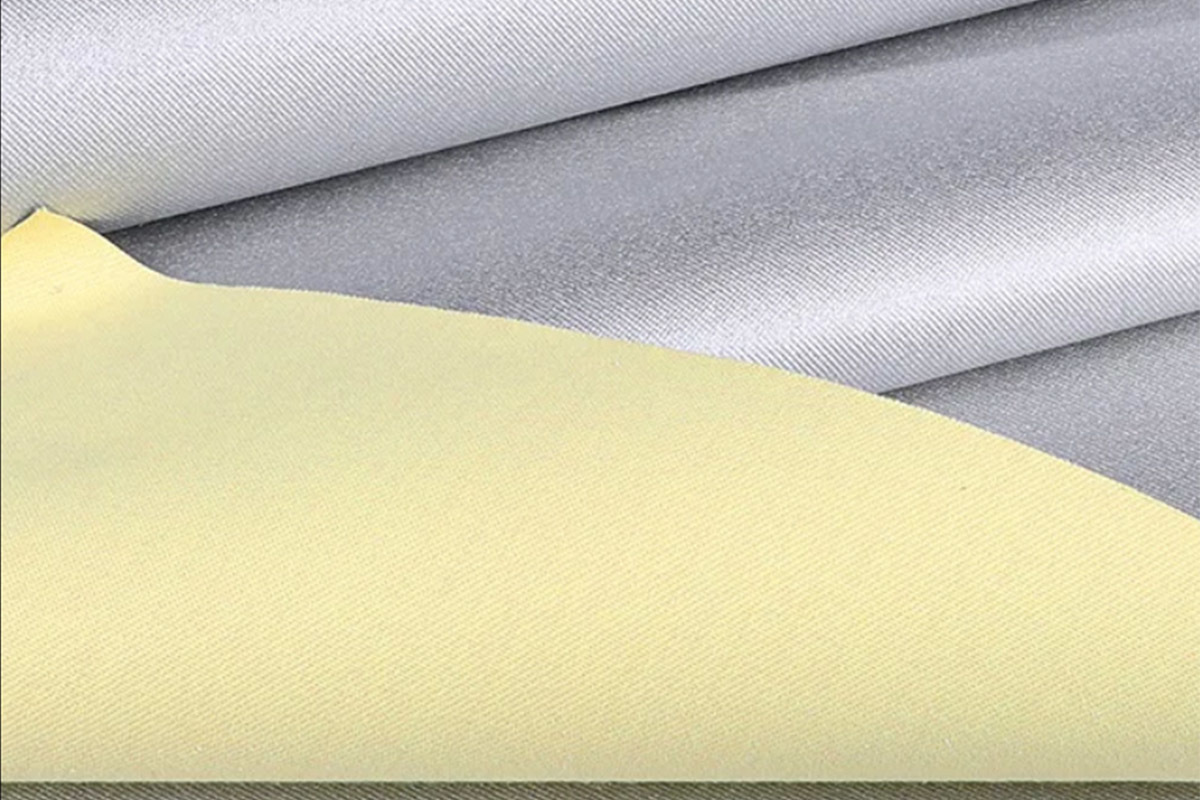

Ultra-high molecular weight polyethylene (UHMWPE) sewing thread, as a high-performance sewing material leading the development trend of modern textile and manufacturing industries, is increasingly demonstrating its irreplaceable and important position. This unique sewing thread stands out among numerous sewing materials due to its extraordinary strength and wear resistance, becoming a leader in the industry. Its molecular weight far exceeds that of ordinary polyethylene materials, and this characteristic endows it with a series of excellent physical properties, making it shine in the sewing field. Compared with traditional sewing threads, UHMWPE sewing thread exhibits superior bearing capacity and stability. It can easily cope with greater tensile force and tension, and is not easily broken even under extreme conditions, thus significantly improving the durability and service life of sewn products. This advantage makes it the preferred material in manufacturing products that require high strength and durability. In addition to its excellent strength and wear resistance, UHMWPE sewing thread also has excellent chemical corrosion resistance and UV aging resistance. This means that no matter what harsh chemical environment or prolonged sunlight exposure the sewn items are subjected to, it can maintain good shape and performance without fading, aging, or damage. This characteristic greatly expands its application fields, making it shine in many fields such as outdoor equipment, automotive interiors, and high-end clothing manufacturing. In the field of outdoor equipment, UHMWPE sewing thread is widely used in the sewing of tents, backpacks, and outdoor clothing. Its excellent strength and wear resistance ensure that these equipment can maintain good working condition even in harsh outdoor environments, providing reliable protection for outdoor enthusiasts. In the automotive interior field, it is used in the sewing of key components such as seats and seat belts, improving the durability and safety of the car interior. In the high-end clothing manufacturing field, UHMWPE sewing thread, with its delicate texture and excellent sewing effect, has won wide acclaim from designers and consumers. With continuous technological advancements and people's pursuit of high-quality life, the application scope of UHMWPE sewing thread will be further expanded. In the future, it is expected to play an important role in more industries and bring revolutionary changes to sewing technologies in various industries. Whether in aerospace, medical devices, or other high-tech fields, UHMWPE sewing thread, with its excellent performance and broad application prospects, will become an indispensable important material in modern industrial sewing technology.

-

Ultra-high molecular weight polyethylene (UHMWPE) sewing thread, with its excellent abrasion resistance, high strength, and low elongation, shows application potential in multiple fields. This sewing thread is not only suitable for sewing traditional textiles, such as high-end outdoor equipment and industrial protective clothing, where extreme environments and heavy loads are required, but is also gradually penetrating high-tech fields such as automotive manufacturing, aerospace, and medical devices, becoming a key link connecting safety and performance. Support for customization of various specifications means that whether it is the precise sewing needs of fine-as-hair threads or the rugged and strong industrial sewing applications, UHMWPE sewing thread can flexibly meet the needs, providing tailor-made solutions for different customers. Its excellent UV resistance and chemical corrosion resistance ensure long-term stability and reliability in various harsh environments, making it one of the indispensable high-performance materials in modern manufacturing.

-

Ultra-high molecular weight polyethylene (UHMWPE) sewing thread plays an indispensable role in modern industry and handicrafts due to its excellent physical properties and numerous applications. This sewing thread boasts extremely high strength and wear resistance, with a breaking strength far exceeding that of traditional materials, making it ideal for sewing heavy-duty, high-strength products such as outdoor gear, safety equipment, and high-end sporting goods. Furthermore, UHMWPE thread exhibits excellent chemical stability, effectively resisting corrosion from most chemicals and maintaining its durability. Its low coefficient of friction ensures smooth stitching, reducing damage to the sewn materials, making it particularly suitable for delicate textiles. With advancements in technology, this high-performance sewing thread continues to expand its applications, from specialized clothing in aerospace to surgical sutures in the medical field, meeting the diverse needs of various industries for high-quality sewing solutions.

Enterprise Advantages

Guangdong Kaidun New Materials Co., Ltd.

The layout of the entire workshop is reasonable, and the equipment is placed in an orderly manner, which not only ensures the smoothness of the production process but also improves work efficiency. Advanced production equipment and technologies are adopted in the workshop to ensure the stability of product quality and the efficiency of production efficiency.

In terms of the environment, the factory workshop effect picture shows a clean and bright production environment. The workshop is equipped with a good ventilation system and lighting equipment, providing comfortable working conditions for workers. At the same time, the workshop also pays attention to environmental protection and energy conservation, adopting environmentally friendly materials and energy-saving equipment to reduce energy consumption and pollution during the production process.

In terms of safety management, the factory workshop effect picture also reflects a high degree of attention. The workshop is equipped with complete safety facilities and warning signs to ensure the safety and health of workers during the production process. In addition, the workshop is also equipped with professional safety management personnel who are responsible for supervising and managing safety matters during the production process to ensure the safety and stability of production.

Production drawing of aramid filament woven fabric

Packaging and delivery of pre-oxidized fibers

Qualification Certification

Various qualification certifications obtained by Kaitun Industrial, demonstrating its professional capabilities in meeting standards in the field of high-performance fiber material textiles, highlighting that its products comply with strict quality, safety and industry regulatory requirements, providing strong support for the enterprise's stable development and market expansion.

Keyword:

Ultra-high molecular weight polyethylene sewing thread

Ultra-high molecular weight polyethylene sewing thread

Still deciding? Get samples first, Contact US !

Products Category

Inquire Now

We will contact you within one working day. Please pay attention to your email.

Related Products

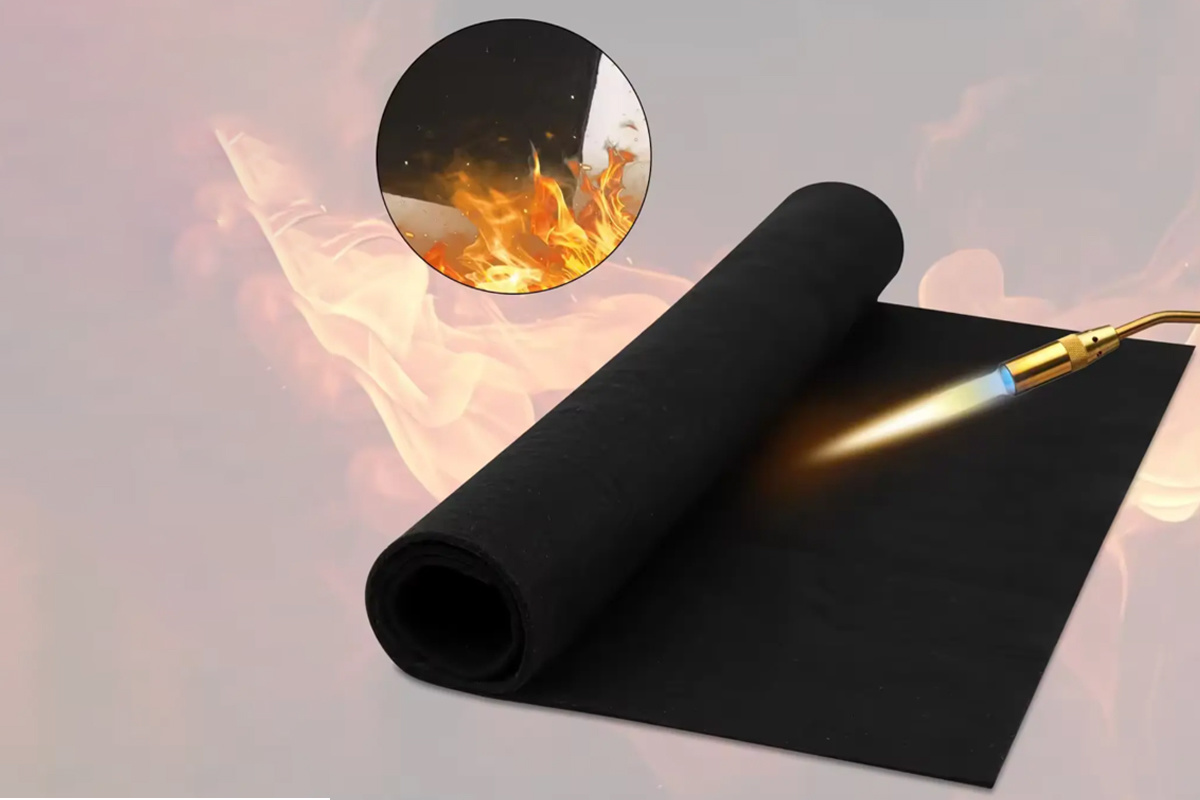

Aramid silver-coated composite fabric