Share to

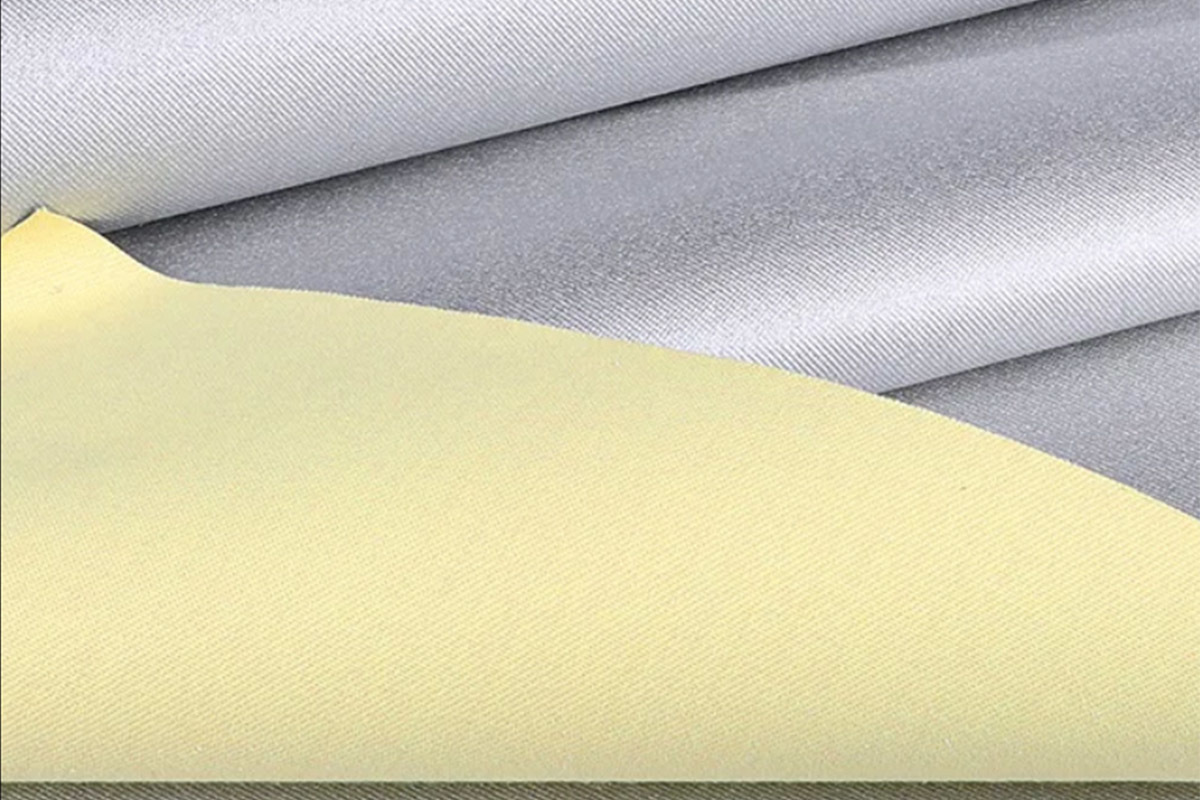

Viscose-based carbon graphite felt

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Features

- Specifications

- Applications

-

I. Origin and Preparation of Viscose-Based Carbon Fiber

Viscose-based carbon fiber, as the name suggests, is a high-performance fiber material made from viscose fiber as a precursor through a series of complex chemical and physical processes. Viscose fiber, as a type of regenerated cellulose fiber, is widely used as a textile raw material due to its good spinnability and environmental friendliness. However, when scientists turned their attention to its potential for high-performance conversion, viscose fiber embarked on a journey to become carbon fiber.

The preparation of viscose-based carbon fiber can be roughly divided into the following key steps: First, high-quality viscose fiber is selected as the raw material. Through pre-oxidation treatment, the cellulose molecular chains in the fiber undergo partial cross-linking and oxidation to form a stable ladder structure. This is the key to ensuring the stable morphology of the fiber during the subsequent carbonization process. Next, carbonization treatment is carried out in a high-temperature inert gas environment, further removing non-carbon elements from the fiber, causing the fiber to gradually transform into carbon fiber mainly composed of carbon elements. Finally, surface treatment and graphitization treatment can further improve the mechanical properties and thermal stability of the carbon fiber.

II. Performance Characteristics: Lightweight and High Strength, Heat and Corrosion Resistant

The reason why viscose-based carbon fiber stands out among many materials is due to its excellent performance characteristics. The most significant is its lightweight and high-strength properties. Its density is only about 1/4 that of steel, but its strength is comparable to that of high-strength steel, even exceeding some alloy materials. This characteristic makes viscose-based carbon fiber an ideal choice for lightweight design in aerospace, automotive manufacturing, and other fields.

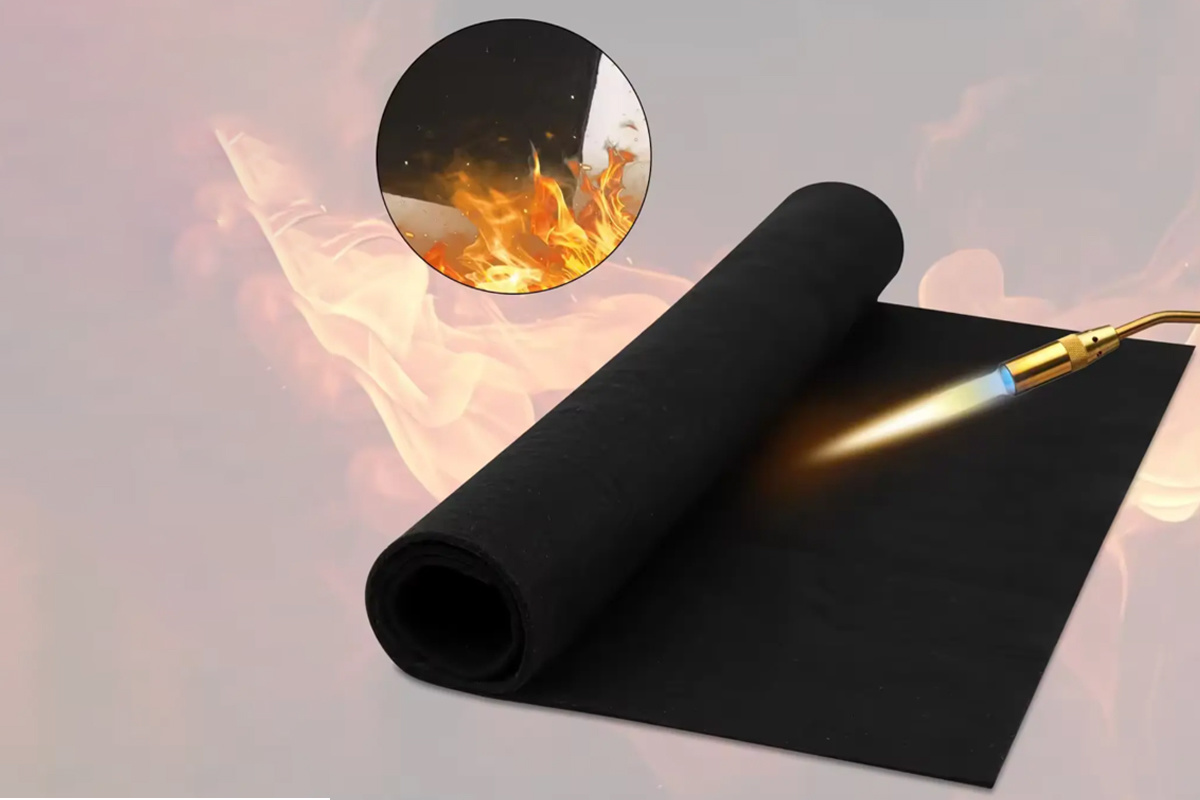

In addition, viscose-based carbon fiber also has good heat resistance and corrosion resistance. In high-temperature environments, it can maintain the stability of its structure and the integrity of its mechanical properties. It is not easy to burn and is not easily corroded by acidic or alkaline corrosive media. These characteristics have enabled viscose-based carbon fiber to find widespread application in industries such as energy, chemical engineering, and medical care that require extreme conditions.

-

Customization supported.

-

III. Application Fields: Wide and Deep

The application fields of viscose-based carbon fiber are extremely wide, covering almost all industries pursuing high performance, lightweight, and corrosion resistance. In the aerospace field, it is an ideal material for manufacturing key components such as aircraft structural parts and engine blades, effectively reducing the weight of aircraft and improving fuel efficiency and flight performance. In the automotive industry, viscose-based carbon fiber is used to manufacture body and chassis components, helping new energy vehicles achieve longer cruising range and higher safety.

In addition, viscose-based carbon fiber also plays an important role in sporting goods, wind power generation, high-pressure containers, deep-sea exploration, and other fields. For example, in sporting goods, it is used to manufacture high-performance tennis rackets and golf clubs, improving the durability and hitting effect of sports equipment; in the wind power generation field, it is used as blade material, enhancing the fatigue resistance and service life of wind turbines.

IV. Future Development Trends and Challenges

Although viscose-based carbon fiber has shown great application potential and market value, its development still faces many challenges. On the one hand, the high production cost limits its popularization in a wider range of fields; on the other hand, the energy consumption and environmental pollution problems in the preparation process are also key issues that need to be urgently addressed. Therefore, the future research and development direction of viscose-based carbon fiber will focus on reducing costs, improving production efficiency, optimizing the preparation process, and developing environmentally friendly production technologies.

At the same time, with the continuous development of emerging technologies such as nanotechnology and composite material technology, the performance of viscose-based carbon fiber is expected to be further improved, and its application fields will be further expanded. For example, through nanomodification, the interfacial bonding force of carbon fiber can be enhanced, improving the overall performance of its composite materials; by compounding with other high-performance materials, new composite materials with specific functionalities can be developed to meet more diversified market demands.

Enterprise Advantages

Guangdong Kaidun New Materials Co., Ltd.

The layout of the entire workshop is reasonable, and the equipment is placed in an orderly manner, which not only ensures the smoothness of the production process but also improves work efficiency. Advanced production equipment and technologies are adopted in the workshop to ensure the stability of product quality and the efficiency of production efficiency.

In terms of the environment, the factory workshop effect picture shows a clean and bright production environment. The workshop is equipped with a good ventilation system and lighting equipment, providing comfortable working conditions for workers. At the same time, the workshop also pays attention to environmental protection and energy conservation, adopting environmentally friendly materials and energy-saving equipment to reduce energy consumption and pollution during the production process.

In terms of safety management, the factory workshop effect picture also reflects a high degree of attention. The workshop is equipped with complete safety facilities and warning signs to ensure the safety and health of workers during the production process. In addition, the workshop is also equipped with professional safety management personnel who are responsible for supervising and managing safety matters during the production process to ensure the safety and stability of production.

Production drawing of aramid filament woven fabric

Packaging and delivery of pre-oxidized fibers

Qualification Certification

Various qualification certifications obtained by Kaitun Industrial, demonstrating its professional capabilities in meeting standards in the field of high-performance fiber material textiles, highlighting that its products comply with strict quality, safety and industry regulatory requirements, providing strong support for the enterprise's stable development and market expansion.

Keyword:

Viscose-based carbon graphite felt

Viscose-based carbon graphite felt

Still deciding? Get samples first, Contact US !

Products Category

Inquire Now

We will contact you within one working day. Please pay attention to your email.

Related Products

Aramid silver-coated composite fabric