Share to

Graphite felt

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Features

- Specifications

- Applications

-

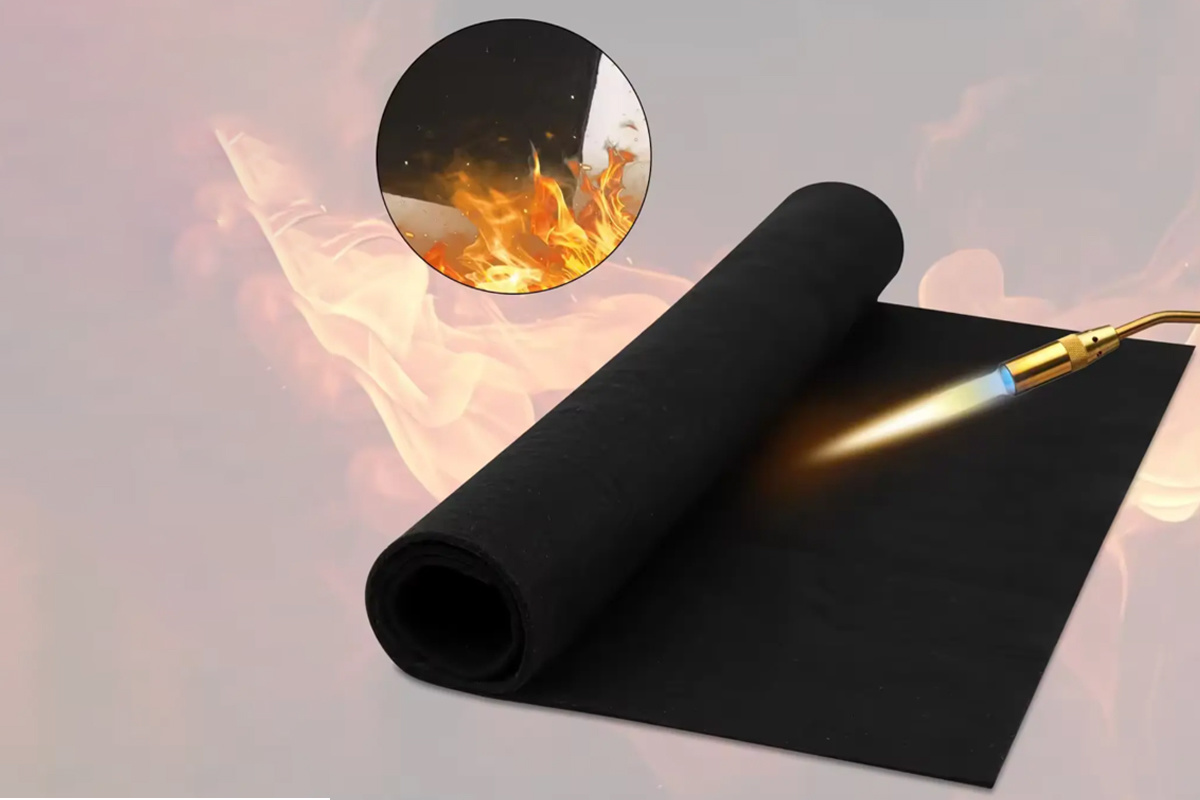

Graphite felt is divided into three types based on the original felt used: asphalt-based graphite felt, polyacrylonitrile-based (PAN-based) graphite felt, and viscose-based graphite felt. Its main use is as insulation and heat insulation material for single crystal silicon smelting furnaces. In the chemical industry, it can be used as a filtering material for high-purity corrosive chemical reagents.

Polyacrylonitrile-based graphite felt has greater strength and better oxidation resistance than viscose-based graphite felt, but it has poor flexibility, high bulk density, and good thermal insulation performance. In addition to having the characteristics of high purity, high temperature resistance, corrosion resistance, and non-melting like block graphite, it also has advantages such as elasticity, the ability to be folded and cut arbitrarily, and can be sewn with graphite yarn. The main use of graphite felt is as insulation and heat insulation material for single crystal silicon smelting furnaces. In the chemical industry, it can be used as a filtering material for high-purity corrosive chemical reagents. Graphite felt can be used at temperatures up to about 3000°C under non-oxidizing atmosphere conditions.

-

Customizable in various specifications

-

① Insulation and thermal insulation materials for single crystal silicon smelting furnaces: Graphite felt is widely used as insulation and thermal insulation materials for single crystal silicon smelting furnaces due to its lightweight, high carbon content, corrosion resistance, high purity, non-volatile at high temperatures, low thermal conductivity, and high-temperature dimensional stability.

② Heat dissipation and electrode materials for electronic devices: In the electronics field, graphite felt is used to manufacture heat dissipation and thermal insulation materials for electronic components. Its high conductivity, low thermal resistance, and good chemical stability make it an ideal choice for making heat sinks and electrode materials, effectively improving the heat dissipation performance and stability of devices.

③ Catalysts and reaction beds for chemical reactions: In the chemical industry, graphite felt can be used to manufacture filtration materials for high-purity corrosive chemical reagents, as well as catalysts and reaction beds for chemical reactions, capable of resisting the erosion of corrosive chemicals and ensuring the stable operation of reactors.

④ Reinforcement and wear-resistant materials for mechanical parts: In the mechanical field, graphite felt can be used to manufacture reinforcement materials and wear-resistant materials for mechanical parts, enhancing the performance and service life of mechanical components.

⑤ Thermal insulation and reinforcement materials for automotive engines: In the automotive manufacturing field, graphite felt is used to manufacture thermal insulation materials and reinforcement materials for automotive engines, improving engine performance and durability.

⑥ High-temperature thermal insulation materials in the aerospace field: Graphite felt is also widely used in the aerospace field, such as in the manufacture of thermal protection materials for rocket engines, capable of withstanding high-temperature gas flow erosion to ensure the safe operation of rocket engines.

Enterprise Advantages

Guangdong Kaidun New Materials Co., Ltd.

The layout of the entire workshop is reasonable, and the equipment is placed in an orderly manner, which not only ensures the smoothness of the production process but also improves work efficiency. Advanced production equipment and technologies are adopted in the workshop to ensure the stability of product quality and the efficiency of production efficiency.

In terms of the environment, the factory workshop effect picture shows a clean and bright production environment. The workshop is equipped with a good ventilation system and lighting equipment, providing comfortable working conditions for workers. At the same time, the workshop also pays attention to environmental protection and energy conservation, adopting environmentally friendly materials and energy-saving equipment to reduce energy consumption and pollution during the production process.

In terms of safety management, the factory workshop effect picture also reflects a high degree of attention. The workshop is equipped with complete safety facilities and warning signs to ensure the safety and health of workers during the production process. In addition, the workshop is also equipped with professional safety management personnel who are responsible for supervising and managing safety matters during the production process to ensure the safety and stability of production.

Production drawing of aramid filament woven fabric

Packaging and delivery of pre-oxidized fibers

Qualification Certification

Various qualification certifications obtained by Kaitun Industrial, demonstrating its professional capabilities in meeting standards in the field of high-performance fiber material textiles, highlighting that its products comply with strict quality, safety and industry regulatory requirements, providing strong support for the enterprise's stable development and market expansion.

Keyword:

Graphite felt

Graphite felt

Still deciding? Get samples first, Contact US !

Products Category

Inquire Now

We will contact you within one working day. Please pay attention to your email.

Related Products

Aramid silver-coated composite fabric