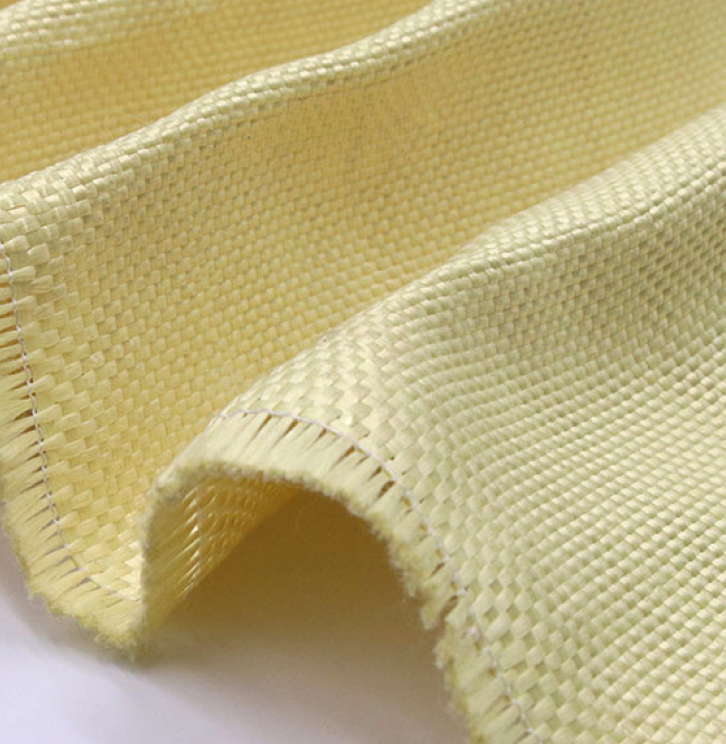

The Bright Future of Niche Materials: Where Will the Next Boom Market for Aramid Filament Fabrics Be?

Jun 26,2025

New Energy Vehicle Sector: Dual Drivers of Lightweighting and Battery Safety

Power Battery Protective Material: The impact resistance and high-temperature resistance (decomposition temperature up to 560℃) of aramid long fiber fabric make it an ideal material for the outer shell of new energy vehicle battery packs effectively enhancing battery safety.

Lightweight Body Components: Aramid composite materials can replace traditional metal materials, reducing vehicle weight by more than 30%, helping to improve cruising range. Approximately 30% of the global demand for para-aramid is used in automotive anti-friction materials. With the increasing penetration rate of new energy vehicles, demand will further increase in the future.

High-End Safety Protective Equipment: Dual Catalysis of Policy and Demand

Firefighting and Industrial Protective Clothing: The implementation of the new national standard "Protective Clothing Flame-Retardant Clothing" has driven the demand for inherently flame-retardant materials. Protective clothing made of meta-aramid not only has excellent flame-retardant properties but also avoids the risk of molten droplets , and the annual growth rate of domestic demand for aramid in the protective clothing field is expected to reach 15%.

Special Equipment: The application of aramid long fiber fabric in special fields such as bulletproof vests and combat training uniforms continues to expand , its strength is 5-6 times that of steel wire, and its weight is only 1/5, making it a core material for lightweight protective equipment.

New Energy and Power Infrastructure: Growing Demand for Insulation and Weather Resistance

Electrical Insulation Materials: The demand for aramid paper (using aramid fiber as the base material) in smart grids and wind power transformers is surging. Globally, 72% of aramid paper is used for electrical insulation , and the domestic market share is even higher, reaching 90%. In the future, with the increase in new energy installed capacity, the application potential of aramid long fiber fabric in cable reinforcement and transformer insulation will be enormous.

Photovoltaic and Wind Power Equipment: Its corrosion resistance and UV resistance make it suitable for offshore wind turbine blade coatings and photovoltaic bracket materials , improving the durability of equipment in extreme environments.

Aerospace and Rail Transit: Lightweighting and Structural Optimization

Aircraft and High-Speed Rail Components: Aramid honeycomb core materials (made from aramid paper) are widely used in aircraft cabin walls and high-speed rail car bodies , which can reduce weight by more than 30% while improving sound insulation and flame-retardant performance. Technological breakthroughs in honeycomb core materials by domestic enterprises will accelerate import substitution.

Satellite and UAV Structures: The lightweight and high-strength characteristics of aramid composite materials meet spacecraft adaptability requirements for extreme environments (such as -196℃ to 300℃). The future development of low-altitude economy and commercial aerospace will further drive demand.

Smart Wearables and Emerging Technology Integration

Smart Fibers and Flexible Electronics: Luminous fibers have been industrialized, and in the future they can be integrated into night running clothing, smart fabrics, and other products; the research and development of fiber-shaped lithium batteries may promote energy solutions for wearable devices.

Medical and Bioengineering: The radiation resistance and biocompatibility of aramid have led to its gradual expansion in applications such as medical protective clothing and artificial ligaments, and it may become an important direction for new medical materials in the future.

[The above materials and data are from the internet and laboratories]

Related Posts

Contact Us

E-mail:

gdkaidun@163.com

Phone/WeChat:

86-131-3828-6677

Address:

Room 401, Building 21, No. 1, Keqing Road, Yundonghai Street, Sanshui District, Foshan City, Guangdong Province